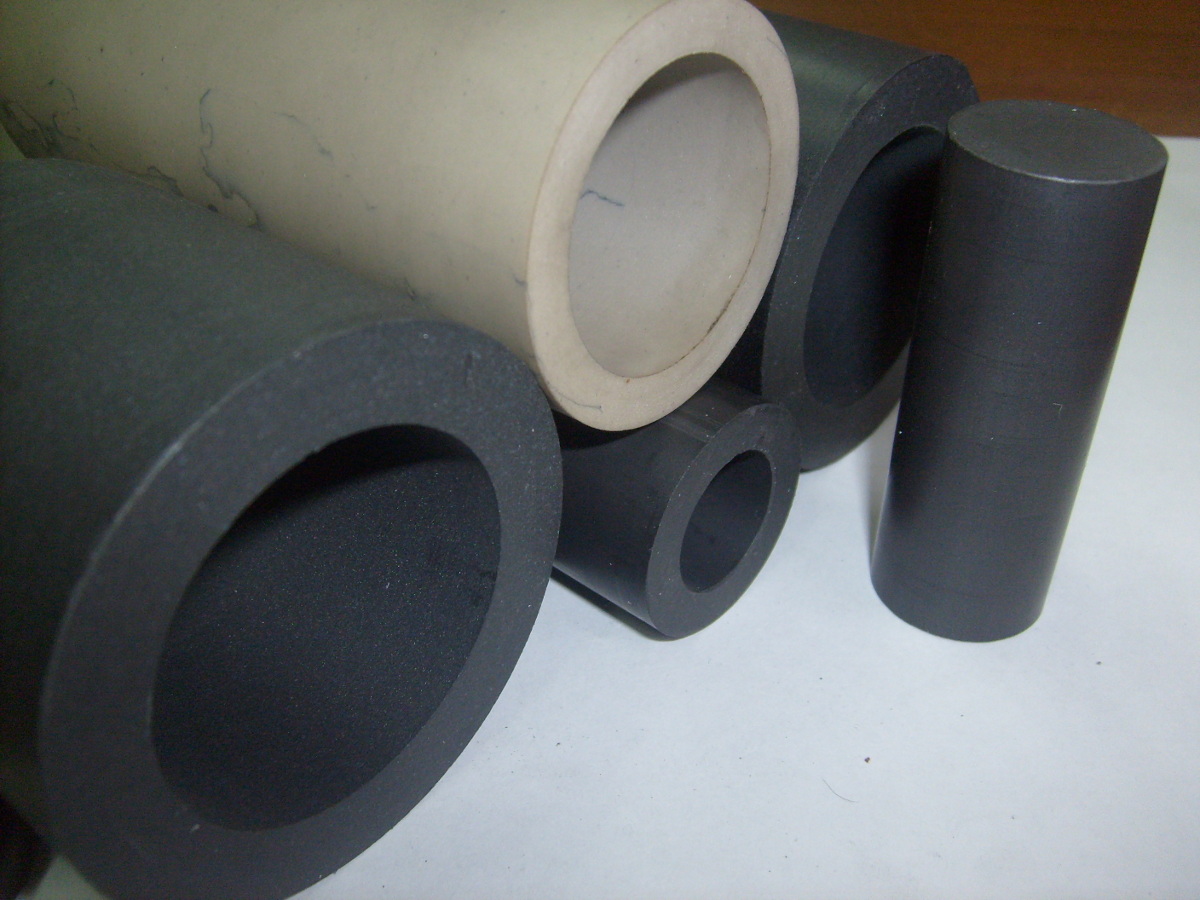

Workpieces for further machining

Constanta-2 LLC manufactures and supplies workpieces in the form of rods, bushings and plates from branded Konstaftor series composite materials developed at our enterprise. Branded materials are compositions based on engineering plastics with improved performance properties. The workpieces are designed for manufacturing of various structural, sealing and antifriction products working in the temperature range from -190 to +300°C by mechanical processing. Konstaftor-200, Konstaftor-300, Konstaftor-300C, Konstaftor-400, Konstaftor-500, Konstaftor-IP are composite materials based on F4 fluoroplastic, and fluoroplastic copolymers (F40, F50, etc.) became the basis of composites with the name Konstaftor Pl. The series labelled Konstaftor-1000 combines materials based on high-temperature resistant polymers: Konstaftor-1000, Konstaftor-1000C, Konstaftor-1000F are composites based on polyether ether ketone with the use of reinforcing and/or antifriction components; Konstaftor-1000 P, Konstaftor-1000 U, Konstaftor-1000 DSV are composites based on polyphenylene sulphide. Branded materials are characterised by increased resistance to pressure and temperature, high wear resistance and antifriction characteristics.

Konstaftor-300С is a composition filled with glass fibre, molybdenum disulphide and modifying additives. In comparison with F4, our material is characterised by a significant decrease in cold-fluid properties, has a wear resistance 2000 times higher, retaining good antifriction properties. At the same time the cost of products made of it is significantly lower than the cost of products made of other compositions of fluoroplastic.

Konstaftor-300 is a F4 composition, with chemically modified carbon fibre as the main filler. The structure of the material provides excellent heat resistance even under the influence of increased pressure and high wear resistance. Products made of it retain high strength and do not deform at temperatures up to +250°C. Moreover as a better analogue of Fluvis material in terms of operational properties, Konstaftor-300 has a lower cost.

Konstaftor-400 is a highly filled composition based on F-4, characterised by increased yield strength, heat resistance and very low creep, especially at high temperatures.

Konstaftor-Pl А, Konstaftor-Pl B, Konstaftor-Pl D - materials based on fluoroplastic copolymers F4 (F40, F50, F-3) containing various fillers: glass fibre, carbon fibre, molybdenum disulphide and modifying additives. These materials are characterised by processability, lack of fluidity under load and greater resistance to temperature and pressure than F4. Konstaftor-Pl D is designed for work at extremely low temperatures down to -196°C. Its application is relevant for equipment for storage and processing of liquefied natural gas (LNG)

Konstaftor IP composition made of fluoroplastic-4 filled with polyester fibres is also available for users.

Based on the Konstaftor-200, Konstaftor-300, Konstaftor-300C, Konstaftor-400, Konstaftor-500, Konstaftor-IP, Konstaftor-IP B, Konstaftor-IP D, Konstaftor SVM, Konstaftor-700, Konstaftor-900, PEEK, Konstaftor-1000, Konstaftor-1000C, Konstaftor-1000F, Konstaftor-G, the following dimensions of bushings are produced by compression moulding:

| Outside diameter, mm | Internal diameter, mm | Height, mm | Outside diameter, mm | Internal diameter, mm | Height, mm |

|---|---|---|---|---|---|

| 17±0,5 | 9±0,5 | 35±1 | 119±1 | 75±1 | 63±1 |

| 27±0,5 | 12±0,5 | 40±1 | 120±1 | 95±1 | 40±1 |

| 27±0,5 | 16±0,5 | 80±1 | 122±1 | 98±1 | 18±1 |

| 27±0,3 | 9±0,3 | 40±1 | 122±2 | 49±1 | 60±1 |

| 28±0,5 | 14±0,5 | 62±1 | 125±1 | 70±1 | 100±2 |

| 28±0,5 | 15±0,5 | 62±1 | 125±1 | 100±1 | 17±1 |

| 30±0,5 | 18±0,5 | 62±1 | 126±2 | 97±2 | 70±1 |

| 31±0,5 | 17±0,5 | 58±1 | 127±1 | 59±1 | 100±2 |

| 32±0,5 | 19±0,5 | 62±1 | 129±2 | 109±2 | 60±1 |

| 32±0,5 | 19±0,5 | 63±1 | 130±2 | 110±2 | 35±1 |

| 36±1 | 22±1 | 62±1 | 140±2 | 95±2 | 35±1 |

| 37±0,5 | 24±0,5 | 62±1 | 140±2 | 110±2 | 50±1 |

| 38±0,5 | 24±0,5 | 63±1 | 140±1 | 121±1 | 43±1 |

| 41±1 | 22±1 | 50±1 | 150±2 | 115±2 | 64±1 |

| 41±1 | 27±1 | 59±1 | 154±1 | 137±1 | 49±1 |

| 43±1 | 29±1 | 40±1 | 164±3 | 143±3 | 58±1 |

| 44±0,5 | 31±0,5 | 62±1 | 167±2 | 138±2 | 125±2 |

| 47±0,5 | 24,5±0,5 | 62±1 | 168±2 | 143±2 | 40±1 |

| 47±0,5 | 32±0,5 | 62±1 | 168±2 | 112±2 | 60±1 |

| 48±1 | 25±1 | 30±1 | 173±2 | 146±2 | 22±1 |

| 50±1 | 30±1 | 62±1 | 175±2 | 150±2 | 43±1 |

| 50±1 | 24±1 | 48±1 | 179±3 | 135±3 | 28±1 |

| 50±1 | 28±1 | 51±1 | 180±2 | 149±2 | 23±1 |

| 52±1 | 30±1 | 15±1 | 190±2 | 155±2 | 35±1 |

| 52±1 | 36±1 | 61±1 | 195±3 | 146±3 | 63±1 |

| 53±1 | 37±1 | 64±1 | 200±3 | 155±2 | 20±1 |

| 55±1 | 40±1 | 60±1 | 204±4 | 165±4 | 65±1 |

| 55±1 | 33±1 | 54±1 | 220±4 | 156±4 | 65±1 |

| 56±1 | 38±1 | 63±1 | 223±3 | 194±2 | 25±1 |

| 57±1 | 19±1 | 70±1 | 225±3 | 185±2 | 20±1 |

| 57±1 | 29±1 | 70±1 | 230±2 | 185±2 | 58±1 |

| 57±2 | 38±1 | 63±1 | 230±2 | 201±2 | 43±1 |

| 58±1 | 18±1 | 50±1 | 236±3 | 197±2 | 26±1 |

| 58±1 | 32±1 | 40±1 | 249±2 | 219±2 | 45±1 |

| 58±1 | 38±1 | 58±1 | 250±3 | 210±2 | 35±1 |

| 59±1 | 35±1 | 80±1 | 254±3 | 148±2 | 30±1 |

| 60±1 | 36±1 | 58±1 | 267±3 | 207±2 | 38±1 |

| 61±1 | 31±1 | 80±1 | 272±3 | 247±3 | 30±1 |

| 62±1 | 34±1 | 80±1 | 284±4 | 239±4 | 65±1 |

| 63±1 | 36±1 | 64±1 | 292±3 | 237±3 | 33±1 |

| 65±1 | 50±1 | 63±1 | 296±2 | 244±2 | 42±1 |

| 66±1 | 30±1 | 80±1 | 304±3 | 148±2 | 30±1 |

| 67±1 | 44±1 | 50±1 | 305±3 | 270±3 | 25±1 |

| 67±1 | 40±1 | 80±1 | 320±3 | 175±3 | 50±1 |

| 68±1 | 52±1 | 60±1 | 327±3 | 259±3 | 57±1 |

| 68±1 | 41±1 | 62±1 | 350±3 | 287±3 | 42±1 |

| 68±1 | 46±1 | 64±1 | 350±5 | 320±5 | 32±1 |

| 69±1 | 14±1 | 70±1 | 385±5 | 360±5 | 32±1 |

| 70±1 | 35±1 | 70±1 | 395±5 | 355±5 | 32±1 |

| 70±1 | 38±1 | 50±1 | 420±5 | 382±5 | 36±1 |

| 70±1 | 42±1 | 60±1 | 437±3 | 405±2 | 60±1 |

| 75±1 | 44±1 | 30±1 | 455±5 | 428±5 | 23±1 |

| 77±1 | 18±1 | 50±1 | 460±5 | 430±5 | 32±1 |

| 78±1 | 46±1 | 90±1 | 483±5 | 383±5 | 57±1 |

| 78±1 | 44±1 | 63±1 | 510±5 | 420±5 | 63±2 |

| 79±1 | 54±1 | 96±1 | 550±5 | 520±5 | 32±2 |

| 82±1 | 33±1 | 62±1 | 590±5 | 555±5 | 32±2 |

| 82±1 | 65±1 | 35±1 | 660±5 | 628±5 | 32±1 |

| 82±1 | 54±1 | 80±1 | 670±5 | 630±5 | 32±2 |

| 90±2 | 64±1 | 80±1 | 745±5 | 708±5 | 25±2 |

| 92±1 | 52±1 | 64±1 | 750±5 | 700±5 | 32±2 |

| 92±1 | 69±1 | 64±1 | 755±5 | 695±5 | 28±2 |

| 92±1 | 72±1 | 64±1 | 850±5 | 785±5 | 30±2 |

| 93±1 | 48±1 | 50±1 | 850±5 | 800±5 | 32±2 |

| 94±1 | 23±1 | 50±1 | 880±5 | 790±5 | 28±2 |

| 94±1 | 50±1 | 60±1 | 885±7 | 830±7 | 32±2 |

| 94±1 | 76±1 | 43±1 | 900±7 | 846±7 | 30±2 |

| 100±2 | 77±1 | 50±1 | 919±7 | 771±7 | 72±2 |

| 102±1 | 40±1 | 26±1 | 955±7 | 902±7 | 32±2 |

| 102±1 | 80±1 | 20±1 | 1017±10 | 850±10 | 85±2 |

| 110±1 | 81±1 | 20±1 | 1055±10 | 995±10 | 30±2 |

| 112±2 | 72±1 | 60±1 | 1065±10 | 985±10 | 35±2 |

| 114±1 | 94±1 | 50±1 | 1065±10 | 1000±10 | 32±2 |

| 115±1 | 70±1 | 80±1 | 1100±10 | 1040±10 | 35±2 |

| 115±1 | 97±1 | 43±1 | 1147±10 | 973±10 | 90±2 |

| 118±1 | 98±1 | 25±1 | 1285±10 | 1225±10 | 35±2 |

| 1300±10 | 1190±10 | 35±2 | |||

| 1355±10 | 1290±10 | 35±2 | |||

| 1376±10 | 1185±10 | 115±2 |

Konstaftor-1000, Konstaftor -1000C, Konstaftor -1000F are materials based on PEEK, a linear-aromatic polyether-etherketone polymer. These materials are suitable for the most severe operating conditions. Temperature of long-term operation under load from -40°C to +260°C while maintaining high strength (up to 200 MPa). Minimum operating temperature - up to -100°C (accompanied by increased brittleness). Maximum short-term operating temperature is up to 300°C. Unique wear and scratch resistance allows to use materials in mating with steel and ceramic surfaces with low friction coefficient 0,2-0,3. Chemical resistance is comparable to the resistance of fluoroplastic F4.

Konstaftor-1000P, Konstaftor-1000U, Konstaftor-1000DSV are materials based on PPS (polyphenylene sulphide). They are offered for harsh operating conditions. Temperature of long-term operation under load from -40°C to +190°C with retaining high strength (up to 80 MPa). The material is used whenever the capabilities of materials based on polyamide, polyoxymethylene and other similar materials are insufficient, and the capabilities of superplastics such as PEEK are excessive and a more economical solution is required.

Konstaftor-700 is a composite material based on PPA (polyphthalamide). It has high strength properties and improved antifriction characteristics. The material has significant heat resistance and retains serviceability under prolonged exposure to temperatures in the region of 200°С. It is recommended as a material for loaded parts.

Konstaftor-DSV PP is a composite material based on PP (polypropylene) reinforced with glass fibre by LFT-technology.

Konstaftor-46 is a composition based on acetal homopolymer POM (polyoxymethylene). It has high mechanical strength, stiffness, hardness and creep resistance as well as a low coefficient of thermal expansion.

Konstaftor-P36 is a composite material based on PA (polyamide). Unlike the original material, this glass fibre reinforced and heat stabilised nylon composite provides increased strength, stiffness, creep resistance and dimensional stability while maintaining excellent wear resistance.

Konstaftor-C, Konstaftor-C65, Konstaftor-C75 are a range of composites based on plasticised PPS (polyphenylene sulphide) reinforced with fibres and antifriction additives. Due to filling with modified fluoroplastic and other additives improving mechanical characteristics, the material has excellent antifriction properties with no creep. It is designed to replace F-4 material and fluoroplastic composites in cases where the use of fluoroplastic is limited due to mechanical loads.

PPS (polyphenylene sulphide), PPA (polyphthalamide), PP (polypropylene), PU (polyurethane), injection moulded bushings are available in the following dimensions:

| Outside diameter, mm | Internal diameter, mm | Height, mm | Outside diameter, mm | Internal diameter, mm | Height, mm |

|---|---|---|---|---|---|

| 42±0,5 | 30±0,5 | 12±0,5 | 301±2 | 278±2 | 20±1 |

| 59±0,5 | 34±0,5 | 39±0,5 | 334±2 | 307±2 | 15±1 |

| 64±0,5 | 40±0,5 | 43±0,5 | 335±2 | 310±2 | 20±1 |

| 70±0,5 | 40±0,5 | 13±0,5 | 353±2 | 329±2 | 20±1 |

| 99±0,5 | 80±0,5 | 22±0,5 | 355±2 | 328±2 | 15±1 |

| 102±1 | 72±1 | 20±0,5 | 356±2 | 325±2 | 28±1 |

| 121±1 | 98±1 | 22±0,5 | 358±2 | 336±2 | 16±1 |

| 127±1 | 100±1 | 23±0,5 | 371±2 | 346±2 | 13±1 |

| 155±1 | 132±1 | 21±0,5 | 378±2 | 351±2 | 13±1 |

| 173±1 | 145±1 | 24±0,5 | 391±2 | 366±2 | 11±1 |

| 184±1 | 154±1 | 18±0,5 | 402±2 | 376±2 | 14±2 |

| 191±1 | 158±1 | 20±0,5 | 433±3 | 406±3 | 13±2 |

| 193±1 | 175±1 | 18±0,5 | 476±3 | 449±3 | 13±2 |

| 221±1 | 195±1 | 26±1 | 515±3 | 508±3 | 14±2 |

| 231±1 | 195±1 | 25±1 | 540±3 | 509±3 | 14±2 |

| 231±1 | 209±1 | 20±1 | 546±3 | 515±3 | 14±2 |

| 236±1 | 202±1 | 20±1 | 554±3 | 524±3 | 15±2 |

| 241±1 | 206±1 | 17±1 | 566±3 | 526±3 | 22±2 |

| 250±1 | 227±1 | 20±1 | 571±3 | 541±3 | 14±2 |

| 252±1 | 214±1 | 26±1 | 640±3 | 609±3 | 13±2 |

| 258±1 | 234±1 | 16±1 | 684±3 | 653±3 | 13±2 |

| 262±1 | 241±1 | 18±1 | |||

| 282±1 | 258±1 | 24±1 |

Rods with diameters of 10 - 85 mm and height up to 100 mm, sheets, meshes and other nonwoven materials with dimensions up to 1000x1000x100 mm are also available.

Operating conditions suitable for workpieces materials:

- operating media: natural gas, oil, petroleum products, ammonia, acids, alkalis, organic solvents, water, steam, other aggressive media;

- maximum operating temperature range: from minus 100 ºC to plus 300 ºC - depending on the grade and composition of the material;

- media pressure: up to 200 MPa;

- radiation resistance: up to 109 rad according to the material grade.

Workpieces are supplied according to TS 22.22.13-015-34724672-2020.

The choice of material is agreed with the manufacturer for specific operating conditions. Constanta-2 LLC is also able to produce bushings from F4 and its compositions (F4K20, F4C15M5, F4U15, AFGM, F4Br).

Назад

Назад