Polymer composite rollers

Conveyor roller is an important component of most conveyors designed for handling various goods. It is used to support a belt or other working element during the operation of a warehouse, material handling or factory conveyor. Rollers can be collapsible or non-collapsible, and used almost in all industries - from food industry to mining, chemical and metallurgical industries.

Bodies manufactured from polymers or polymer based composites are quite widespread. It is related to low weight and cost. Moreover, the polymer application in the roller design (both individual parts and the whole roller) makes the use of rollers non-alternative in conditions where traditional materials are not applicable like high humidity, corrosive environment, high abrasive wear, etc.

Polymer composite roller

Conveyor roller design

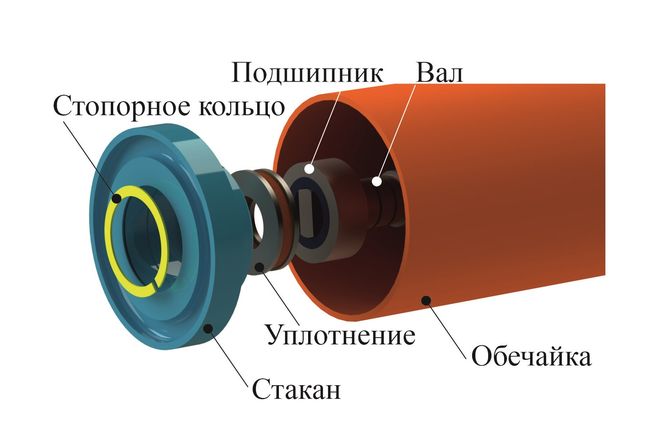

A common conveyor belt roller is represented by a relatively simple design, which provides a long service life. Structural features of the roller from polymer and composite materials are as follows:

- Outer shell. It is made of various types of elastomers, polymers and composites that meet the specified operating conditions.

- Shaft. Made of various types of steel and special polymers in case of high aggressive media.

- Bearing. Bearing. Rolling bearings from polymer composite materials as well as metal-polymer sliding bearings can be used.

- Seal. A rubber or rubber-metal seal that prevents external contaminants from entering the bearing unit.

- Cup. Manufactured from polymers and composites to meet the specified operating conditions. This is the side cover of the roller and the housing of the bearing unit.

- Retaining ring. It is made of polymers and prevents the bearing unit elements from falling out.

Design features of the disassembled roller

Назад

Назад