Сhevron seals, О-rings, sealings, wipers

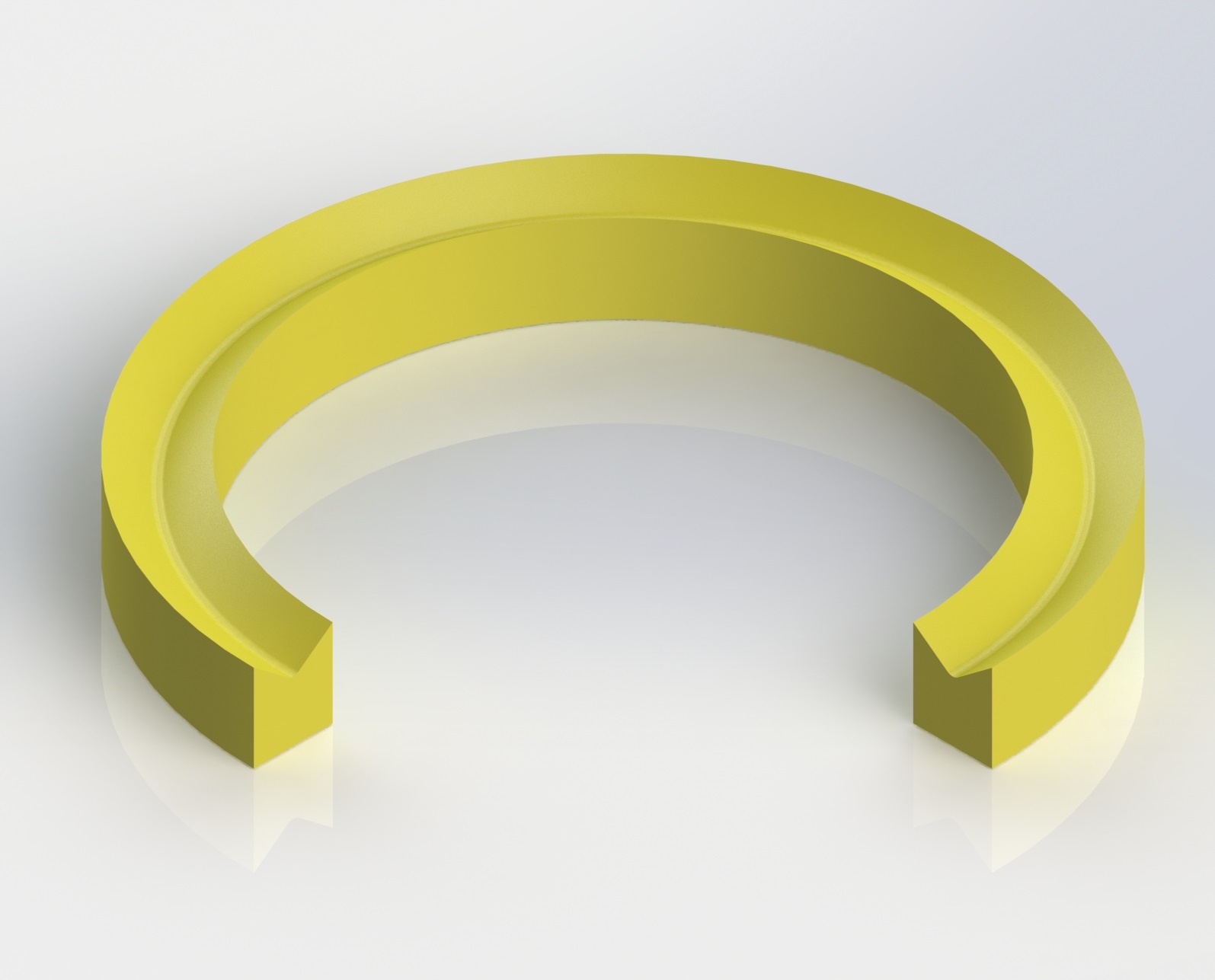

1. Сhevron seals, pressing and supporting rings.

Chevron seals are designed for sealing gaps between cylinder and rod, plunger in pump units and hydraulic devices with diameter up to 1000 mm, operating at pressure up to 70 MPa with reciprocating speed up to 5 m/sec.

Seal dimensions according to GOST 22704-77 or customer's design.

Diameter: from 8 to 800 mm.

Operating temperature: up to 250°С

Pressure: p ≤ 70 MPa

Operating media: mineral oils, acid and alkali solutions, oil, water, solvents.

The sealing is manufactured from special purpose rubber, reinforced rubber, rubber cord, polyurethane and dynamic thermoplastic elastomers and can be equipped with support and pressure rings made of fluoroplastic, polyamide, polyetheretherketone.

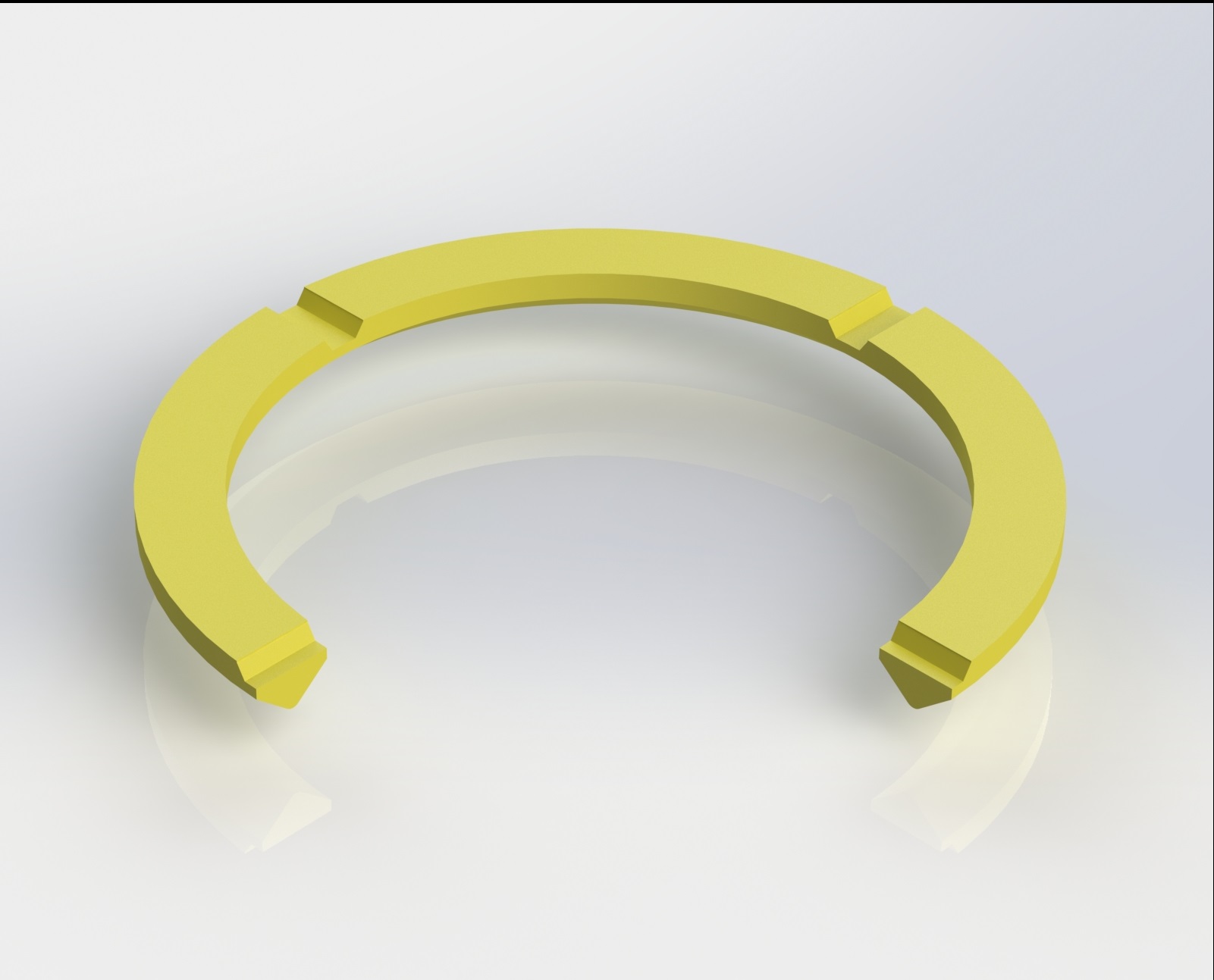

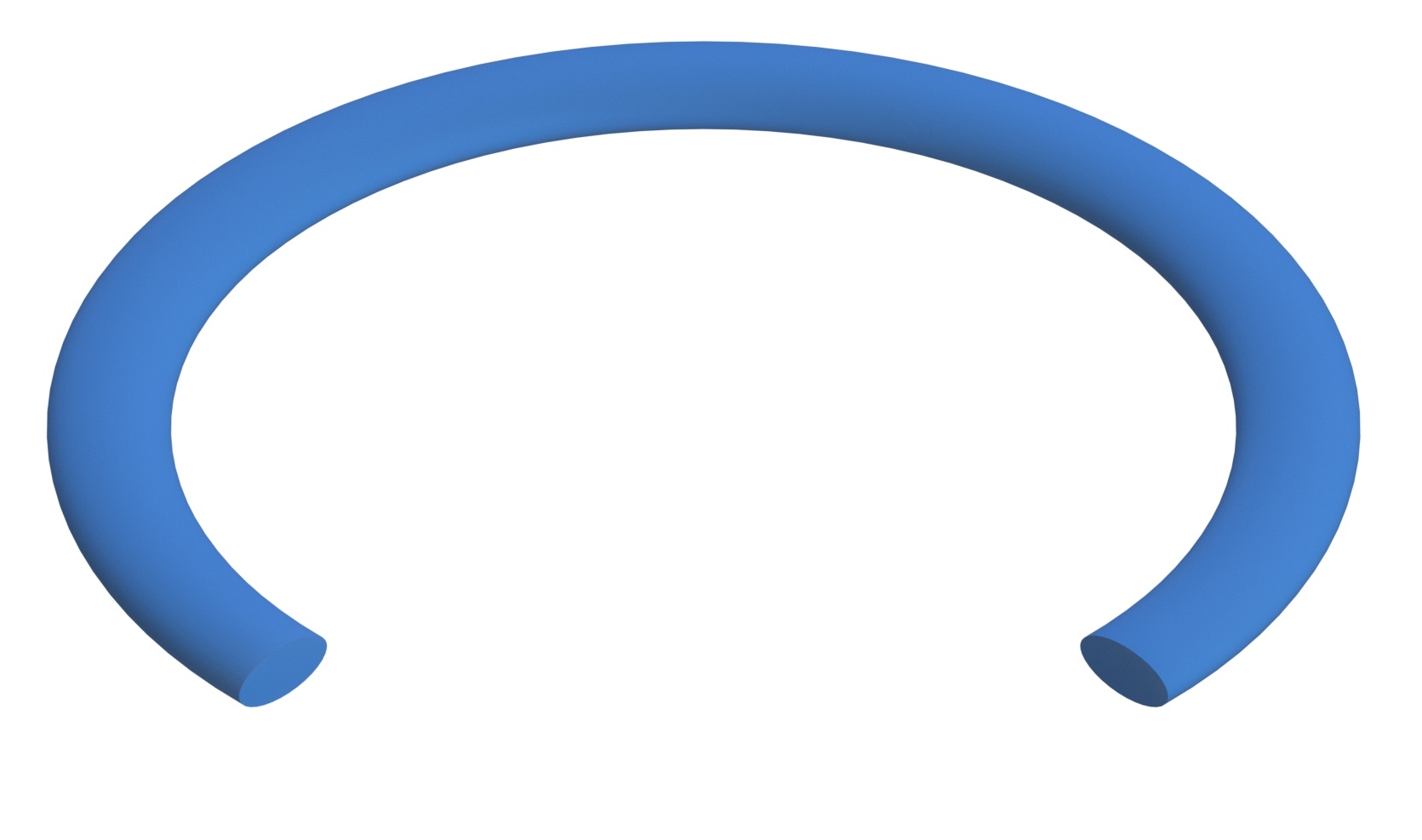

2. O-ring, R-ring, Oval ring and Х-ring

A breakthrough in the development of sealing technology is associated with the creation of oil and petrol resistant rubbers on the basis of synthetic rubbers (elastomers). Unique properties of rubber and possibilities of technology of moulding products from it allowed to create various designs of highly hermetic, simple, cheapest and universal seals. The most universal of them are O-rings, widely used since 40-s in all areas of machine-building.

O-rings are supplied according to GOST 9833-73 or according to customer's design drawings.

However, in spite of the fact that O-rings and R-ring are an excellent solution for sealing fixed joints, their application in mobile joints is limited.

So a significant disadvantage of O-rings is the tendency to twist under the action of friction forces, leading to loss of tightness and damage to the rings, increasing with increasing diameter. In case of good lubrication of rings there is no torsion up to the diameter of 150 mm.

Oval rings are designed for sealing moving joints in diameters of 50 - 500 mm. Unlike O-rings, they do not twist and are therefore more reliable in operation. Their service life reaches that of O-rings. The disadvantages of oval rings are increased friction force and width of the assembly.

X-rings are torsion-resistant, more dynamically tight than O-rings, and generate lower friction forces due to optimised distribution of contact pressures. The lateral undercuts help to reduce friction forces at high pressure on the sliding elements. Small dimensions and double-acting property of X-rings determine their preferential application as seals of movable joints of hydraulic cylinder pistons.

Internal diameter: up to 1700 mm

Operating temperature: up to 300°С

Material: general and special purpose elastomers, polyurethane and dynamic thermoplastic elastomers.

Our technologies allow us to produce rings of almost unlimited internal diameters from certain types of elastomers!

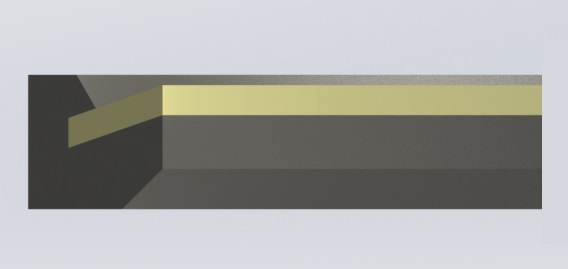

3. Packing seals for hydraulic and pneumatic equipment

Seals are designed to tighten the gap between the cylinder and piston (plunger, rod) in hydraulic and pneumatic equipmnet operating in reciprocating motion with a speed of relative displacement not more than 0.5 m/sec, at a pressure from 0.1 to 50 MPa, temperature from - 60 to +200 ° C depending on the group of rubber, frequency of operation up to 0.5 Hz.

Dimensions correspond to GOST 14896-84 and GOST 6678-77

Diameter D: up to 1000 mm

Material: general and special purpose elastomers, thermoplastic elastomers

4. Wipers

Dimensions correspond to GOST 24811-81

Назад

Назад