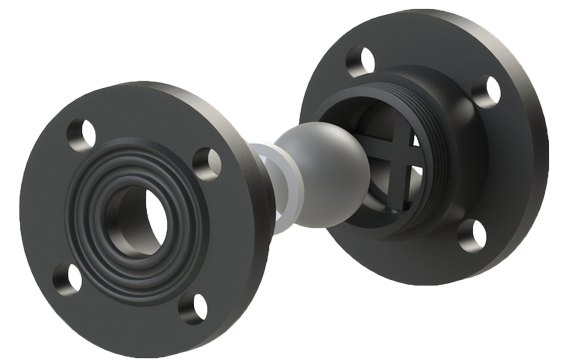

Ball reverse-flow valve

BALL REVERSE-FLOW VALVES FROM POLYMER COMPOSITE MATERIALS ТS 28.14.11-044-34724672-2022

Reverse-flow valves are designed for installation as protective pipeline valves for shutting off and opening the return flow of the operating media in the pipeline depending on the requirements of the technological process (open-closed cycle) during transportation of various media, including aggressive chemical, abrasive as well as oil and gas products. Reverse-flow valves are produced in accordance with technological documentation and production technology of Constanta-2 LLC».

- Reverse-flow valves can be applied:

The composite solution provides low valve weight, guarantees high chemical resistance of the valve, excellent performance properties as well as a lifetime preserved appearance of the shut-off unit. These qualities are determined by the features and advantages of composite polymer materials, which are increasingly replacing metals in new designs of equipment and assemblies. For example, composites based on ultra-resistant plastics are used for the manufacture of the body and disc, providing high abrasion resistance, combined with universal chemical tolerance, which makes the composite solution more attractive for use than the option of using a metal body and disc. The non-metallic reverse-flow valve is the result of a synthesis of the best available technologies in the processing of polymer and composite materials.

The developed composite reverse-flow valves are designed to close the return flow of the working medium of pipelines for pumping various media, including aggressive chemical, abrasive as well as oil and gas products. In addition, the universal chemical resistance of composites used for the production of reverse-flow valves and high inertness of these materials allow to recommend this version of reverse-flow valves for food and biological media as well.

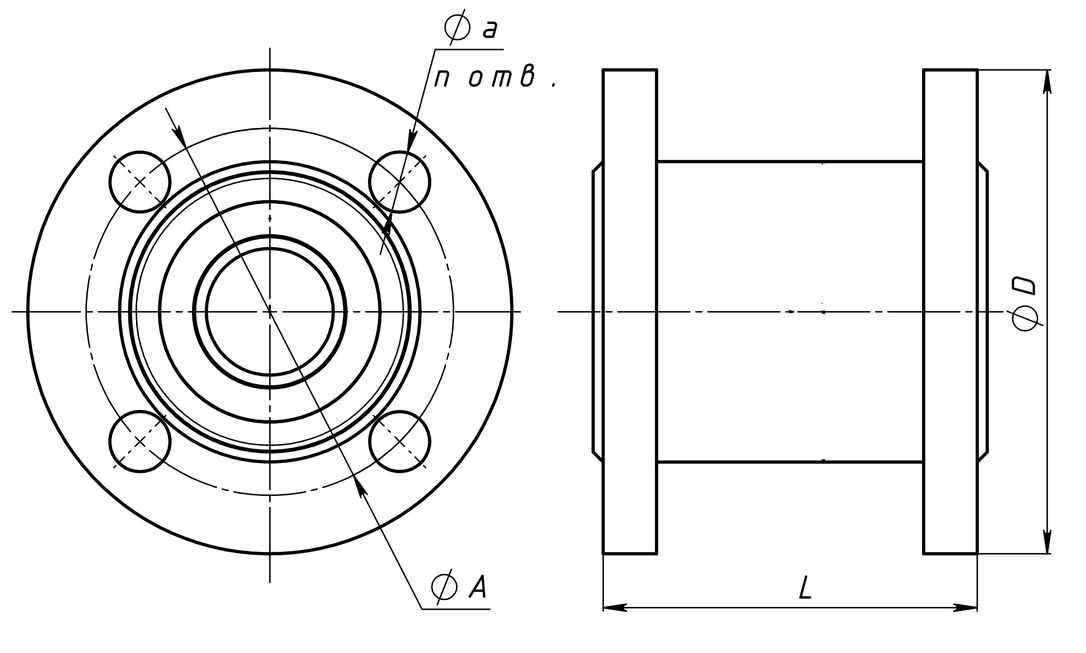

| DN, mm | Overall and connecting dimensions, mm | Weight, kg max * | ||||

|---|---|---|---|---|---|---|

| D, mm | L, mm | A, mm | a, mm | n, mm | ||

| 20 | 105 | 59 | 75 | 14 | 4 | <0,7 |

| 25 | 115 | 70 | 85 | 14 | 4 | <1,1 |

| 32 | 135 | 98 | 100 | 18 | 4 | 1,5 |

| 40 | 145 | 112 | 110 | 18 | 4 | 1,8 |

| 50 | 160 | 134 | 125 | 18 | 4 | 2,4 |

| 80 | 195 | 156 | 160 | 18 | 8 | 4,3 |

| 100 | 230 | 190 | 190 | 22 | 8 | 7,1 |

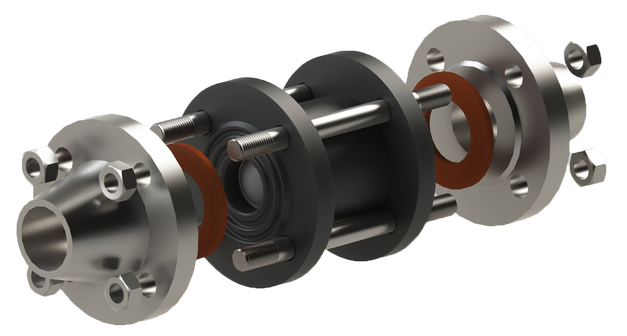

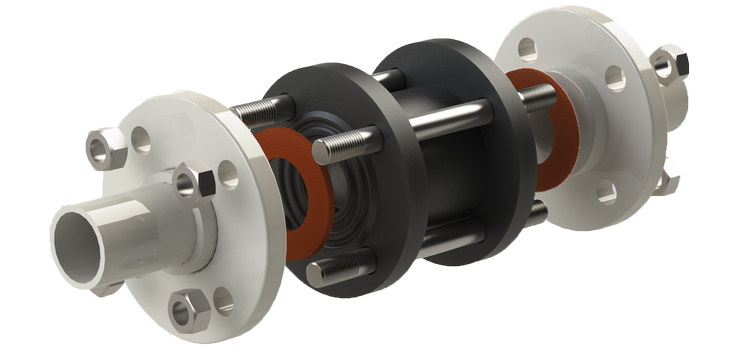

Installation guidelines

Brief description of the reverse-flow valve from polymer composite materials produced Constanta-2 LLC:

| Description | Value |

|---|---|

| Service life: | minimum 5 years |

| Resource: | minimum 400000 cycles |

| Pressure PN: | from 0.6 to 1.6 MPa |

| Operating media temperature | from -50°С to + 150°С |

| Ambient temperature | from -70°С to +50°С |

| Operating conditions | NF 2; 2.1 in accordance with GOST 15150-69 |

| Body material: | composite on the basis of thermosetting and thermoplastic resins Konstaftor-G, Konstaftor-1000P |

| Leakage class: | А in accordance with GOST R 54808-2011 |

| Connection of reverse-flow valve to pipeline | flange, interflange |

| Flange connection dimensions | in accordance with GOST 33259-2015 |

| Direction of media flow | unilateral |

| Operating media: | petroleum products; chemically active liquids (acidic and alkaline with and without mechanical inclusions); domestic, industrial and sea water; steam; food and biological media; hydro- and pneumatic pulses with particle size up to 2 mm. |

Назад

Назад