Sliding bearings

We kindly ask you to fill in our Questionnaire if you are interested in our products and would like to place an order for production. This will help to provide all the necessary information and save the time.

1.Metal polymer sliding bearings

A sliding bearing is a support or guide in which the journal (shaft bearing surface) slides on the surface of the insert (bearing). Bearings are divided into radial bearings (radial load bearing) and axial thrust bearings (axial bearing) (axial load bearing). When radial and axial loads are applied together, combined supports are used in which the axial load is taken up by the ends of the shells or special ridges.

Polymer sliding bearings are used: for shock and vibration loads; for precision bearings with constant rigidity; for bearings with small radial dimensions; for particularly large and miniature bearings; for operation under extreme conditions (high temperatures, abrasive and aggressive media).

Sliding bearings are used in steam and gas turbines, pumps, valves, compressors and other machines.

Metal polymer sliding bearings or tape, sheets from which they are made are a multilayer composite material and designed for operation in friction units without lubrication of many types of equipment, where the use of lubrication is inadmissible or highly undesirable, as well as in the presence of lubricating and cooling media. These sliding bearings do not require special maintenance, are self-lubricating, they achieve a significant reduction in the coefficient of friction due to the use of antifriction fluoroplastic layer.

Our company offers its customers not only import-substituting products - metal-polymer bearings (MPB), developed and produced at our plant, surpass in its characteristics both foreign and local analogues, providing an opportunity to replace traditional MPB or products of European manufacturers, improving the performance of the unit and reducing costs. The differences of our MPB are provided by a special way of fixing and reinforcement of the working layer of these seals. Metal polymer bearings consisting of a metal substrate, an adhesive sublayer and a fluoroplastic layer reinforced with glass fibre cloth, differ significantly from bearings made of metal-fluoroplastic tape (MFT), which are a layer of fluoroplastic 50 microns thick, cohesively connected with fluoroplastic pressed into a porous bronze layer, which, in turn, is clad on a metal substrate. MPB produced by Constanta-2 LLC are devoid of the disadvantages accompanying the use of bronze in the composition of the product. They have high chemical resistance to such problematic for products of other manufacturers substances as hydrogen sulphide, sulphuric acid, methanol and other aggressive agents.

Metal fluoroplastic bearings combine low friction coefficient, small dimensions with high bearing capacity, insensitivity to temperature fluctuations, which cause its wide application. Bearings made of metal fluoroplastic tape withstand static load of 250 MPa and dynamic load of 180 MPa with friction coefficient of 0.1 - 0.2. Metal fluoroplastic bearings withstand static loads of 400 MPa and dynamic loads of 250 MPa with a low coefficient of friction in the range of 0.05 - 0.1.

Metal polymer bearings are produced in two types:

The first type is made of mesh with different mesh size and wire thickness from steels 20, 12Х18Н9Т, bronze, brass, copper. Fluoroplastic 4PN, compositions based on fluoroplastic such as F4S15М5, F4К20, Konstaftor 300, Konstaftor Pl, or composition based on polyetheretherketone Konstaftor 1000 are used as an antifriction layer.

The second type is produced on a metal plate made of St3, 08ps, 12X18N10 (08X18N10T) steels, aluminium. The antifriction layer is a composition based on glass fibre reinforced or metal mesh fluoroplastic F-4D or compositions based on polyetheretherketone Konstaftor 1000, polyoxymethylene, ultra-high molecular weight polyethylene.

Metal polymer bearings are produced in accordance with TS 4791-008-347246723-2009 ‘Metal polymer sliding bearings’ (Specifications are available upon the request).

Example of designation according to TS:

MPB 2 AU 350-65-2,5 TS 4791-008-347246723-2009

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| MPB | 2 | А | У | 350 | 65 | 2,5 | TS 4791-008-347246723-2009 |

Where

1. Product type:

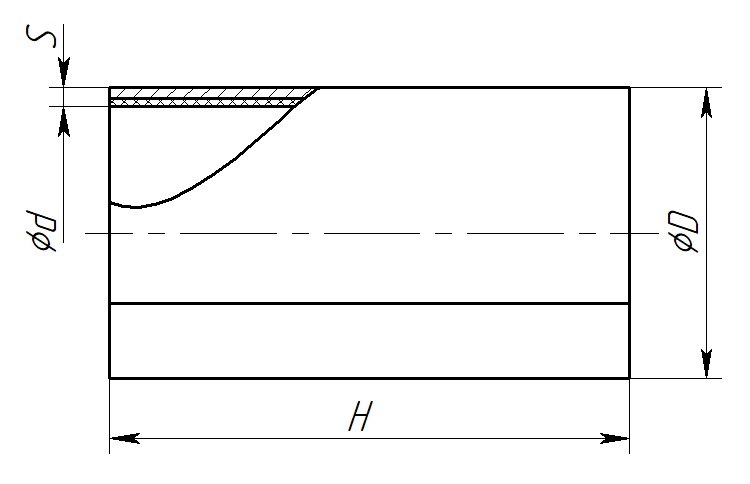

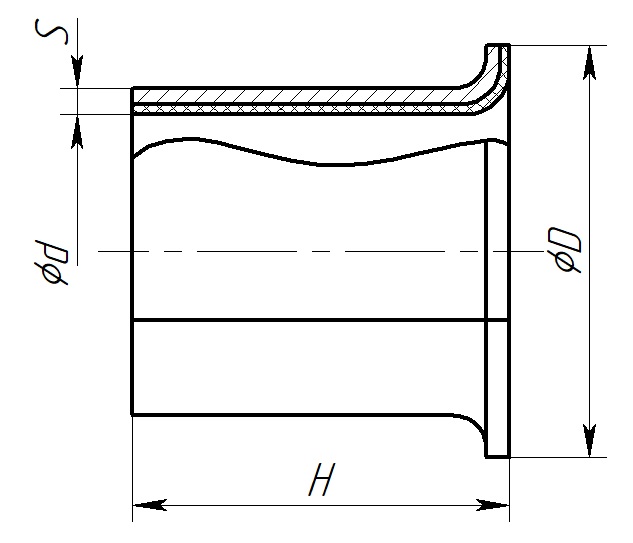

- MPB – Metal polymer radial bearing - wrapped bushing (Pic. 1а, Pic. 1b);

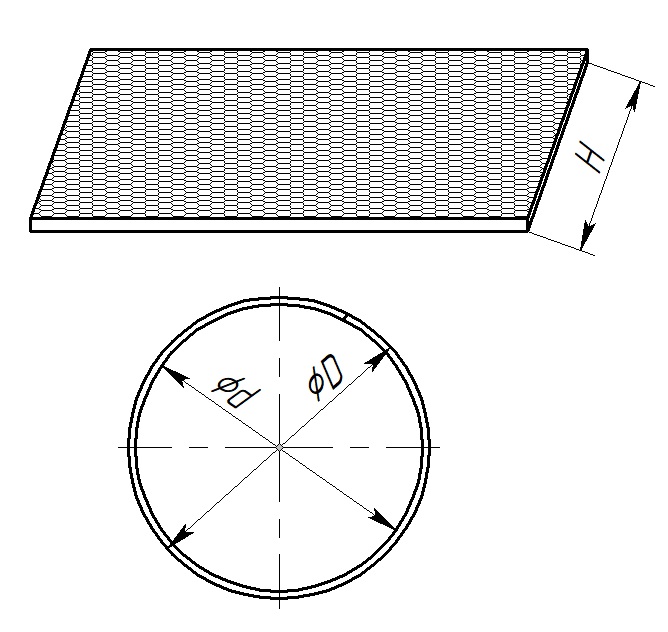

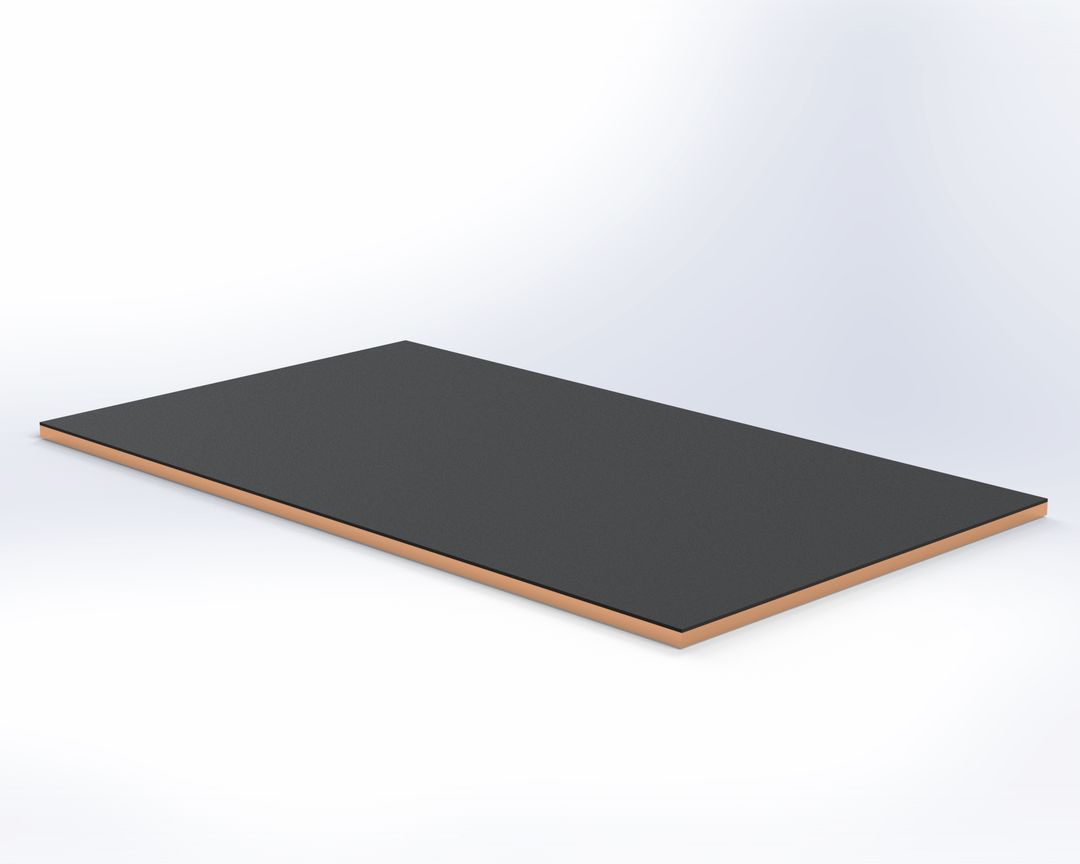

- MPS - Metal polymer sheet (tape) (Pic. 2);

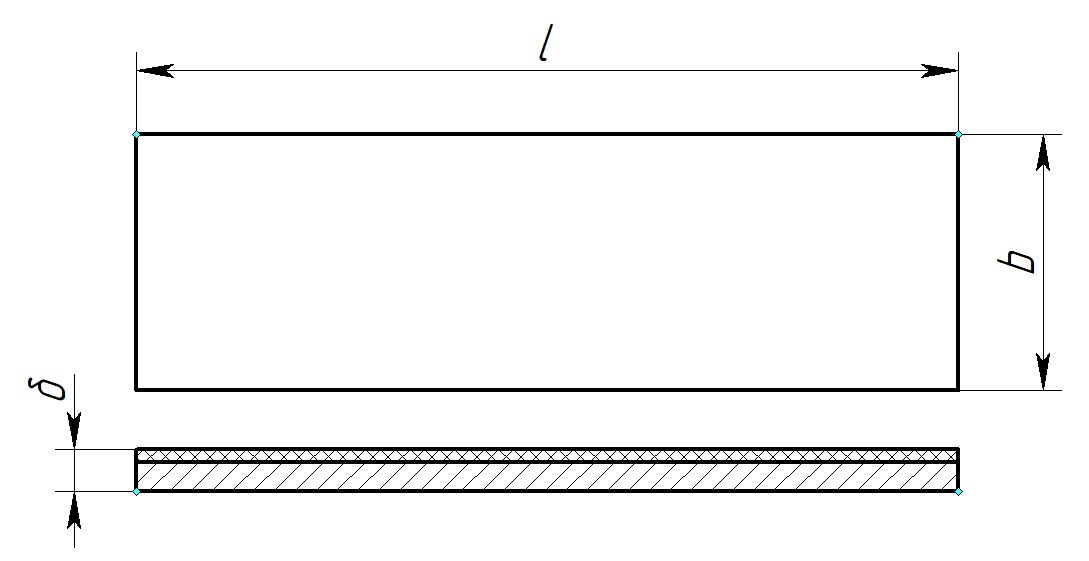

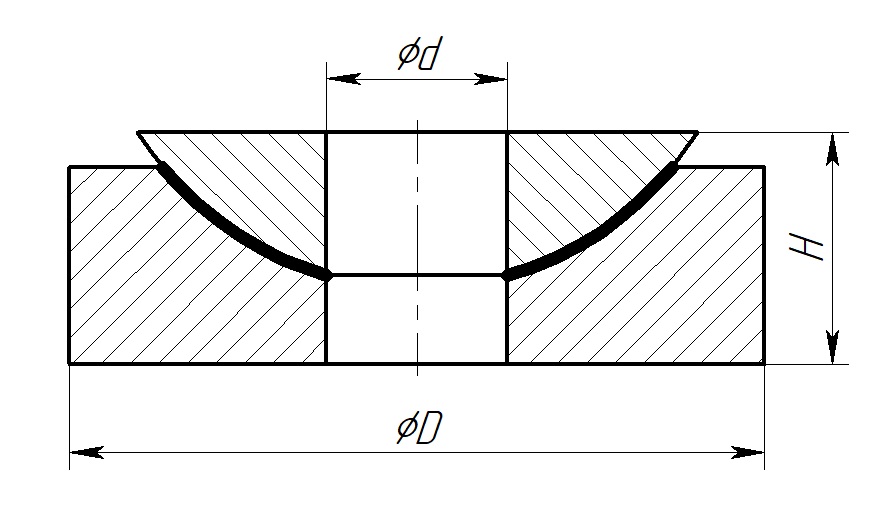

- MACFB - Angular contact flange bearing (Pic. 3);

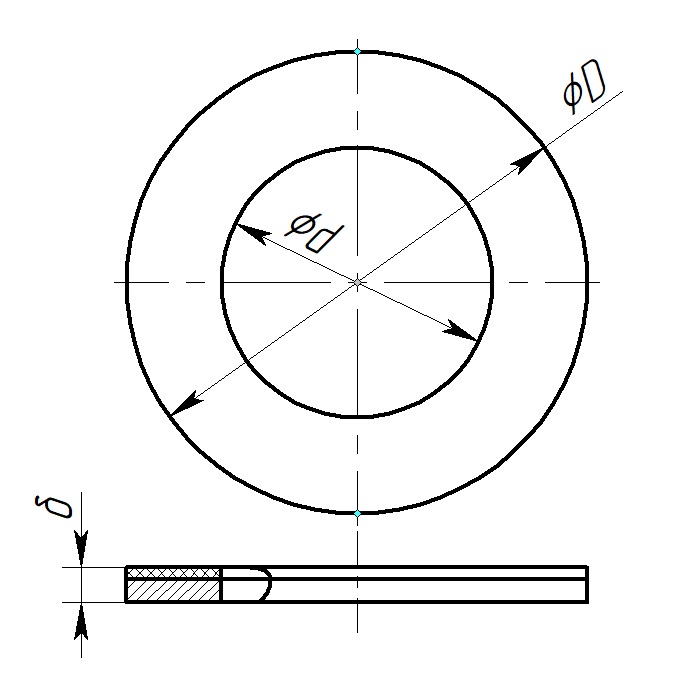

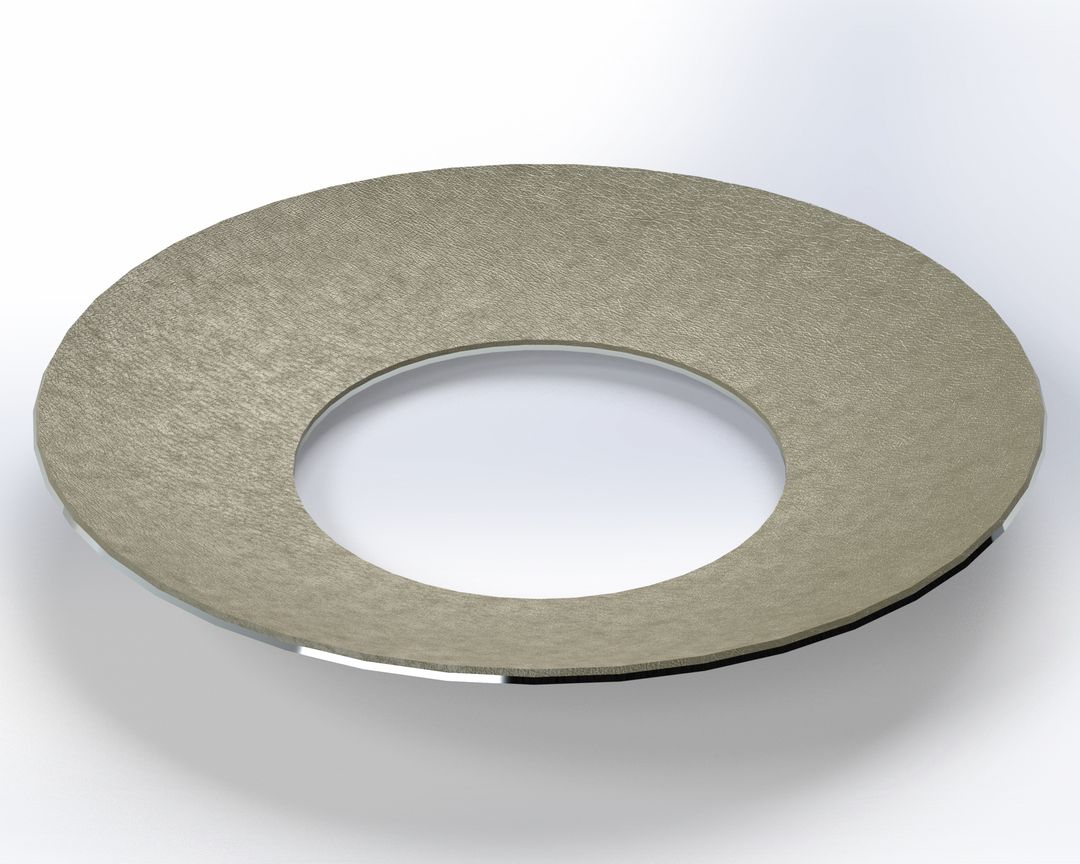

- MPTB - Metal polymer thrust bearing (ring plate) (Pic. 4);

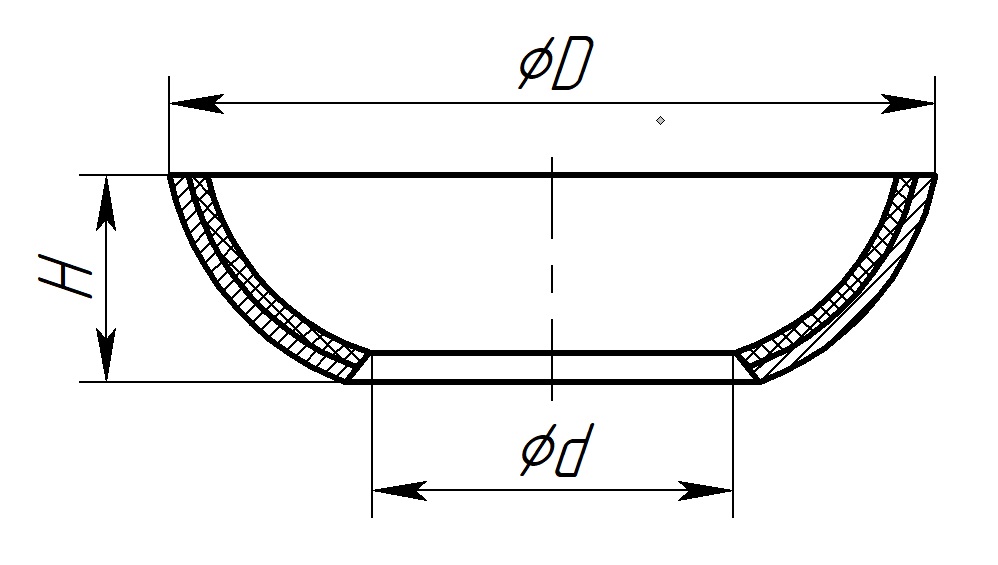

- MPSB - Metal polymer spherical bearing (Pic. 5);

- MPI - Spherical bearing insert (рис. 6).

Pic.1b

Pic.2

Pic.3

Pic.4

Pic.5

Pic.6

2. Bearing type:

3. Sliding layer material:

4. Substrate material:

5,6,7. Geometric dimensions:

Bearings are periodically tested on a special test stand, allowing measurements of the number of rotation cycles, bearing load, coefficient of friction, torque during rotation, bearing wear after cycling.

Применение

Bearings are used in the mechanical engineering, food, textile, pulp and paper, chemical and oil and gas industries in rotating units in valves and pumps.

Unlubricated bearings are preferable for equipment operating under heavy loads in corrosive environments where it is impossible to use bearings with a bronze layer.

The application in cryogenic equipment is caused by comparable values of linear expansion coefficient of bearings with metals and preservation of antifriction properties of polymer layer at low temperatures.

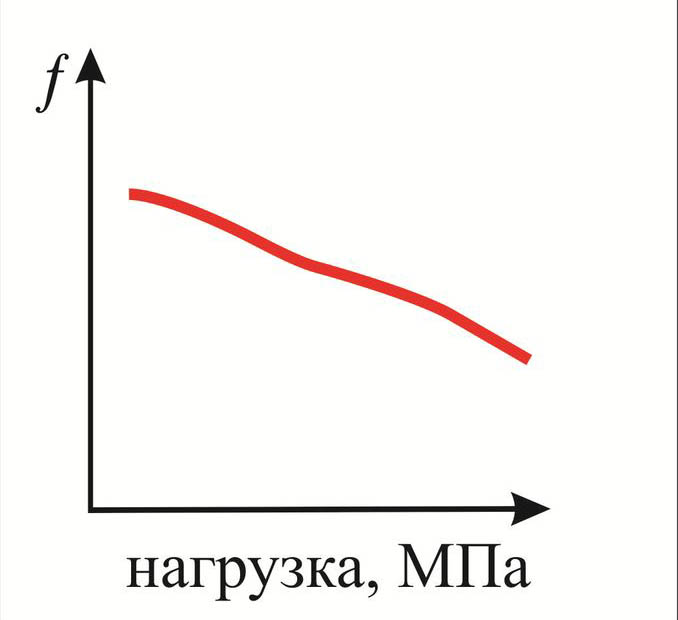

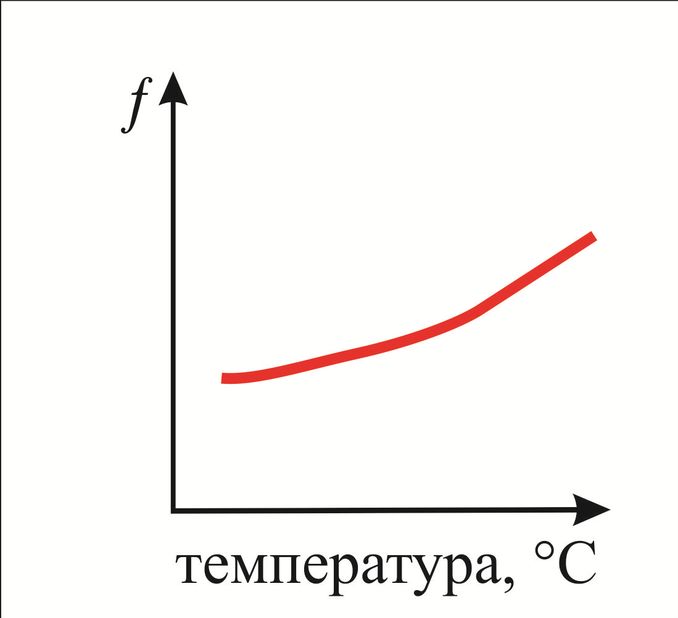

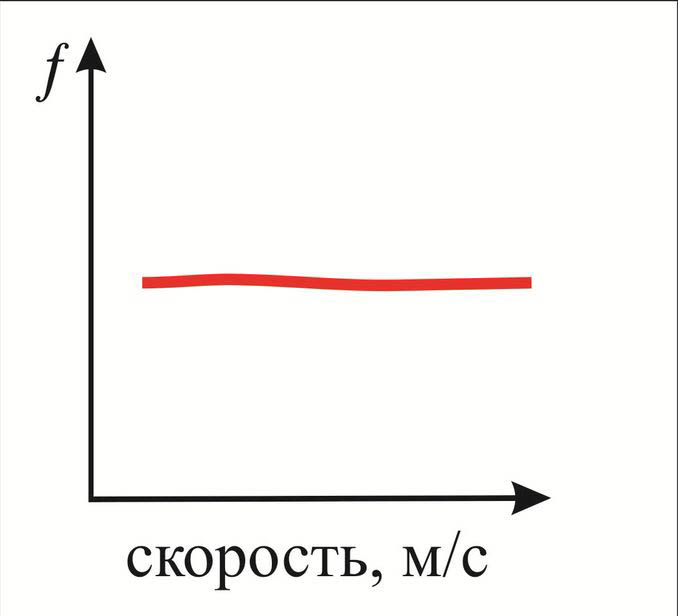

The main characteristics of plain bearings are permissible loads in static, dynamic and transient modes, friction coefficient.

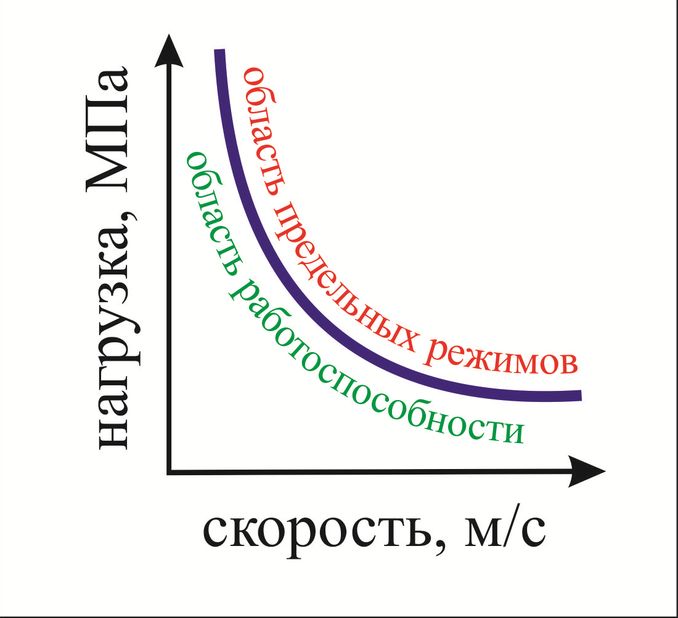

An important parameter determining the performance and durability of sliding bearings is the parameter pV, where p - pressure in the bearing in MPa, V - linear sliding velocity in m/s. This value is different for dry and liquid sliding friction, which is explained by the conditions of heating and heat transfer in the bearing unit. For metal-fluoroplastic bearings in dry friction this value is not more than 1 MPa - m/s. In case of lubrication it can reach 2.5 MPa - m/s.

Bearings with antifriction layer from Konstaftor-1000 or Konstaftor-1000P have higher limiting values of pV and higher coefficient of friction.

When pV increases, the load capacity of plain bearings decreases as durability, expressed in loading cycles, operating time or travelled distance, decreases. So at V approximately equal to 0 m/s (static loading) pmax reaches 400 MPa, at V up to 0,01 m/s (dynamic loading without oscillations) pmax is not more than 250 MPa. In case of strong shocks, oscillations, misalignments, etc., increased speed pmax is reduced to 50 MPa. If there is lubrication in the bearing unit, all other conditions being equal, its service life increases and the sliding speed limit increases too.

We hope that this simple guideline will help in the initial design phase. In addition, the final design of the bearing unit will require knowledge of:

- intended layout;

- operating temperature;

- media characteristics (if liquid friction);

- surface roughness of the mating surfaces;

- nature and magnitude of external influences on the bearing unit.

Bearing operating conditions:

- working media: natural gas, oil, petroleum products, organic solvents, ammonia, acid and alkali solutions and other aggressive media, as well as water and steam;

- operating temperature range: for antifriction layer based on fluoroplastic - from minus 200ºС to plus 250ºС, for antifriction layer from Konstaftor 1000 (polyetheretherketone based material) - from minus 200ºС to plus 280ºС;

| Major diameter D, mm | от 8 до 2000. from 8 to 2000. Preferred thicknesses: 1 mm; 1.1 mm; 1.5 mm; 1.6 mm; 2 mm, 2.1 mm; 2.5 mm; 2.6 mm. External and internal chamfers are provided on the end faces to facilitate bearing and shaft entry. The dimension of the chamfers is 0.5x450 or determined by the drawing. |

| Thickness h, mm | from 0.5 to 3 |

| Layer material | Carbon steel (St3, 08ps), low-alloyed (09G2S), stainless steel (08X18N10T, 12X18N10T, AISI304, AISI316), brass, copper, steel mesh (08X18N10T, St3), aluminium alloys and other variants by agreement. |

| Sliding layer material | Reinforced fluoroplastic or polyetheretherketone |

| Operating temperature, °С | -270 - +280 |

| Static capacity, MPa | 400 |

| Maximum dynamic pressure, MPa | 250 |

| Maximum variable (oscillating) load, МPa | 80 |

| Maximum sliding speed without lubrication, m/s | 1,5 |

| Maximum speed with lubrication, m/s | 5 |

It is possible to manufacture bearings on a metal substrate made of steels by spraying a thin layer of polymer composite with subsequent heat treatment.

If necessary, grease holes or grease grooves are produced in the bearings. Dimensions of lubrication holes and grooves correspond to GOST ISO 3547-3-2006 or according to agreed drawings.

According to the Customer’s agreement bearings can be supplied with protective zinc coating with thickness of 9 microns (Z9) according to GOST 9.306-85, or processed by other methods: anodising, aluminising, in order to exclude corrosion process.

Please find below the preferred bearing dimensions and tolerances, other dimensions and tolerances are produced by agreement:

2. Sliding bearings for special applications

2.1. Bronze-graphite bearings (TS 28.15.23-029-34724672-2016) represent a ring made of special sorotites of copper-aluminium alloys with pressed-in graphite or Teflon grease. They can work without lubrication at high temperatures. It is applicable at metallurgical and steel foundries, in the manufacture of furnaces and steelmaking equipment.

| Operating temperature, °С | up to +450 |

| Static capacity, MPa | 150 |

| Maximum dynamic pressure, MPa | 90 |

| Maximum sliding speed without lubrication, m/s | 0,5 |

2.2. Wear-resistant bearings manufactured from ultra-high molecular weight polyethylene, polyamide, polyether ether ketone with antifriction fillers. These sliding bearings are widely used in mechanical engineering and instrumentation due to their excellent wear resistance and high seizure resistance in the absence or insufficient quantity of lubricant.

| Operating temperature, °С | up to +250 |

| Maximum dynamic pressure, MPa | 100 |

| Maximum sliding speed with lubrication, m/s | 10 |

Please find below the list of bronze-graphite bearings produced:

3. Antifriction, wear-resistant, anti-adhesion, corrosion-resistant coatings for parts of pumps, stop valves, pipelines.

Our company has developed the application of coatings based on high-temperature resistant polymers, which allows us to offer import substitution of equipment parts used today by Russian production, as well as to use the advantages of these coatings in newly developed products of mechanical engineering.

Coatings based on polyetheretherketone allow to increase sharply chemical and corrosion resistance, anti-adhesion properties, wear resistance, reduce the coefficient of friction of the surface of products made of metals, ceramics, used in the chemical industry, medicine and electronics. Coatings with thickness of 300-600 microns are applied by electrostatic spraying of PEEK powder with particle size 30-80 microns, for smaller thickness aqueous dispersions are used. Sintering and polymerisation of coatings are performed at 400 °C.

Polyphenylene sulfide is also widely used for obtaining coatings on metal parts against corrosion at high temperature. Such coatings are obtained by melting PPS compositions and then curing them at temperatures above the melting point (285 °C). Partially cured compositions, depending on the degree of curing, are designed for spray coating and other methods. In addition to PPS, polytetrafluoroethylene is added to produce anti-adhesion hard wear-resistant coatings.

PPS coatings are optimised for the protection of oil pipelines, valves, fittings, couplings, vessels for aggressive liquids (e.g. thermoelectric cells). PPS coated carbon steel parts replace products from expensive alloys.

Coating thickness: up to 600 µm.

Operating temperature: -150 - +250 °С

Materials: fluoroplastic 4 (PTFE), fluoroplastic F4MB (FEP), F-50 (PFA), ultra-high molecular weight polyethylene (UHMWPE), polyetheretherketone (PEEC), polyphenylene sulphide (PPS). The coatings are applied from powders or suspensions in an electrostatic field with subsequent melting in furnaces..

Назад

Назад