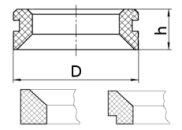

Ball valve seals

Ball valve seat seals shall be made of a flexible material that ensures a tight fit and prevents the sealing surface of the ball from being damaged. At the same time the material shall be strong enough to withstand high specific loads. One of the most universal materials for manufacturing seats is fluoroplastic-4 or its composites. Wide application of PTFE for various operating conditions is connected with its low dry friction coefficient, high chemical resistance and wide range of operating temperatures. In cases when valves operate at cryogenic temperatures fluoroplastic-3 is used. Capron is used for high pressures, low temperatures and non-aggressive liquids and gases. Rubber seats and polyurethane seats have the best sealing ability, but they are recommended at low pressures and in a narrow temperature range.

The seals are designed for sealing the ball and spindle in ball valves and shall provide tightness not less than class A according to GOST 9544.

Manufactured in accordance with TS 2291-005-347246723-2008..

Seal operating conditions:

- Operating environment: natural gas, oil, petroleum products, ammonia, acids, alkalis, organic solvents, water, steam, other aggressive environments;

- Operating temperature range: from minus 190 ºC to plus 250 ºC, depending on material grade and composition;

- Environmental pressure: up to 100 MPa;

- • radioresistance: up to 1099 rad, depending on material grade.

The seals are manufactured from:

Konstaftor® brand materials

- Konstaftor 300 – Fluoroplastic F-4 composite with modified carbon fibre

- Konstaftor 300 С – Fluoroplastic F-4 composite with glass fibre and sliding components

- Konstaftor 400 – Highly filled fluoroplastic F-4 composite

- Konstaftor Pl – materials based on fluoroplastics F-50 (Teflon PFA) and F-40 (Tefzel)

- Konstaftor IP – Fluoroplastic F-4 composite with polymer fibre

- Konstaftor 1000 – polyether ether ether ketone (PEEK) based compositions with optimised antifriction and strength properties

- Konstaftor 1000P – polyphenylenesulfides (PPS) based compositions with optimised antifriction and strength properties

- Konstaftor 700 – polyphthalamide (PPA) based compositions with optimised antifriction properties and heat resistance

- Konstaftor 46 – polymethyleneoxide (POM) based compositions with high mechanical strength and low thermal expansion coefficient

- Konstaftor P36 – polyamide (PA) based composition with optimised strength properties and wearability

- Konstaftor С – polyphenylenesulfides (PPS) based composition with fluoroplastic filler with optimised sliding and strength properties

or from standard polymer sealing materials

- fluoroplastic F-4 in accordance with GOST 10007-80

- filled fluoroplastic compositions

- F4K20 coke filled composition

- F4G graphite-filled composition

- F4UV15 carbon fibre filled composite

Назад

Назад