Metal processing services

Contact the marketing department of Constanta-2 LLC to find out the cost of metal processing services

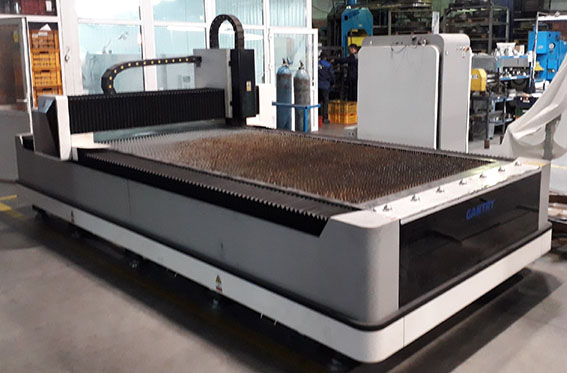

1. Metal sheet laser cutting

Highly accurate laser cutting of metal provides precise workpieces with a smooth edge. For professional cutting of metal sheets contact specialists of Constanta-2 LLC. We use a modern Gweike LF3015LNR Fiber laser, which provides accuracy, precision and high productivity.

Laser cutting services are relevant for various industries: construction, industrial, advertising and many others. The use of laser provides an even edge without defects, and modern computer technology guarantees the highest possible accuracy.

The machine is equipped with a CNC system which minimises human involvement in the process. The positioning accuracy is improved to ±0.03 mm. With the help of such machining it is possible not only to cut sheet materials, but also to make complex parts with patterns and bends, including on thin sheets.

We work with various types of materials. Laser cutting of stainless steel, steel, aluminium, copper and other metals is available. Additional processing of the received blanks is also available upon request. Please contact our specialists to find out exact prices.

2. Laser marking and engraving

The modern laser machine is a very flexible tool. A laser engraving machine can be used for different materials, processes and obtain different results.

Laser marking or laser engraving are very common definitions for laser engraving machines. They are distinguished by the intensity of the surface treatment with laser radiation and the amount of material removal by laser radiation.

Laser marking involves local heating of the product surface. Metals change colour under the influence of high temperature of laser radiation and removal of metal with a layer thickness of 0.5-3 microns can occur. Laser marking is obtained by creating a colour contrast in the treated areas compared to the untreated areas of the product. This colour contrast can be obtained either by alteration by oxidation or by making changes to its structure.

Information is simply applied with laser marking, which is often required for industrial products (plates, tags, instrument panels). The laser marker is used to mark information according to the customer's requirements: logo, manufacturer's name, device model, series and date of manufacture.

Laser marking applied with laser markers is very flexible, fast, special templates are not required, reliable as there is no need to work with ink or other additives, laser marking is resistant to physical and chemical effects such as heat, solvents, greases, etc.

Laser engraving can be divided into conventional laser engraving and deep laser engraving. Ordinary laser engraving does not exceed a depth of 50 microns in the field of laser technology, while deep laser engraving starts from 50 microns and up to 1 mm in the depth of the material to be processed. Generally, laser engraving is used for decoration of jewellery and consumer goods. Laser engraving is often used for engraving weapons (knives, swords, hunting weapons, etc.). In comparison to traditional mechanical, diamond or hand engraving, laser engravers make engraving much faster. Productivity is much higher when using laser engravers.

The equipment available in our company can perform both laser marking and laser engraving successfully.

3. Mechanical metal processing.

Mechanical processing is processing of steel products and other materials by means of mechanical action with the use of a cutter, drill, milling cutter and other cutting tools. The machining process itself is performed on metal-cutting machines in the prescribed manner according to the technological process.

Constanta-2 LLC provides services in complex metalworking, as well as design, production, repair and maintenance of moulds and tooling.

The production base is represented by modern highly accurate imported CNC equipment (turning, milling, machining centres). The company is well equipped with software for writing technological programmes for CNC machines.

The use of new techniques and functional equipment allow us to perform machining of metal in shortest possible time. All works are performed in accurate compliance with existing norms and standards.

Modern technologies for metal processing are used in the process of machining works. The company provides a wide range of services for milling and turning of metals, and is ready to carry out work in accordance with the technical specifications of the customer.

The most popular type of equipment is vertical milling and lathe and boring lathes. They are suitable for the most common and demanded types of work: milling of planes, turning of large diameter products, drilling, countersinking. They can be used for machining moulds, frames, grooves, gears, spiral elements, dies and more. These machines are perfect for both batch and one-off production (customised orders).

Numerically controlled machines are distinguished from conventional machines by their better performance and higher precision. They make all types of machining easier, including the machining of extremely precise, fancifully shaped parts, with no tolerance for even minor errors. Thus, even complex machining can be performed efficiently and fast, while the price can remain affordable: CNC machines reduce the cost of manipulation.

Назад

Назад