Plastic pipe systems

The main material used for many years in the creation of pipeline systems, both domestic and industrial, was various grades of steel, subjected to anti-corrosion treatment if required. But such pipes, along with many advantages, had certain disadvantages, which made manufacturers and scientists look for new solutions and materials. Such materials were polymers, which revolutionised all areas of industry at the end of the twentieth century.

Nowadays plastic pipes are used practically in all fields. The advantages of plastic pipes favourably distinguish them from any other type of pipes and make them practically indispensable both for private installation and for the creation of serious industrial systems.

One of the most important advantages of plastic pipelines is their long service life. In comparison with steel pipes, plastic products are able to last 2-3 times longer, manufacturers give a guarantee for up to 50 years, which ensures that the pipes do not need to be replaced for a long time.

Plastic pipes are well resistant to corrosion, due to the inability of polymers to enter into any electromechanical reactions. Therefore, plastic pipes can be used for installation of both internal and external systems, where the influence of various external negative factors is noted, without additional insulation. Plastic pipes have excellent environmental characteristics. No hazardous substances and toxic materials capable of badly affecting the environment and human health are used in their manufacture.

The installation of polymer pipe pipelines does not require heavy equipment, as well as the presence of high qualifications of the person performing the work. Nowadays, specialists use several types of connections, the choice of the most suitable one is based on the type of polymer, the pipe dimension and the purpose of the pipeline to be assembled.

The main types of connections:

• Socket.

This type of connection is used if plastic sewer pipes are to be connected when assembling a gravity-flow system. In other words, it is suitable for pipelines that operate without pressure.

• Adhesive connection.

There are two possible options for installation - an ordinary adhesive connection or the method of ‘cold welding. The latter uses adhesive compositions, which dissolve the upper part of the polymer. In other words, the connection of adhesive parts is carried out at the molecular level. The last method is used to assemble a pipeline of PVC pipes, for sewerage systems, water and gas pipelines installation.

• Threaded connections.

This type of installation is used where it is necessary to connect a metal pipe to a plastic pipe.

• Temperature welding.

This connection type involves heating of parts at special installations, and then docking of the welded parts. It results in the process of diffusion welding, when molecular particles of one part of the pipe penetrate into the structure of the other.

Specialists of Constanta-2 LLC apply all methods of work with plastic pipeline systems and perform the whole range of services related to their application, including:

• As part of products and design solutions.

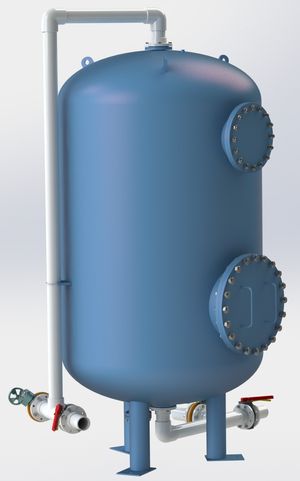

Constanta-2 LLC has been on the market for many years designing and manufacturing lines involved in various industrial and chemical processes (such as galvanic production, preparation of chemically active solutions, chemical processing of various products and semi-finished products, etc.). As a part of these lines are widely used tanks, baths, filters and other equipment made of polymeric materials, which due to their high corrosion resistance not only have a great advantage over traditional "iron" solutions, but often is the only possible solution. The use of plastic piping systems in these projects is a logically justified extension of all the above-mentioned advantages.

• As part of corrosion protection works at the customer's site.

Corrosion protection works performed by specialists of Constanta-2 LLC on the territory of the customer's enterprise often include the modernisation of current systems of reagent supply to the tank equipment being repaired. Application of plastic pipelines significantly simplifies and speeds up the installation process. This is especially important for large-sized tanks, where large-diameter pipes are used in communications. The use of metal pipes, which have a large mass, requires the use of serious lifting equipment, and sometimes even lifting equipment. Plastic pipes provide less costly solutions. The relevance of plastic pipelines increases significantly as the tightness of installation works increases.

• As independent projects for the manufacture of industrial pipelines.

Specialists of Constanta-2 LLC often have to perform works on replacement of worn-out communications or laying new ones. The use of plastic pipes is practically non-alternative due to all the above-mentioned advantages (with rare exceptions related to the conditions required by the customer).

• In the form of component supplies.

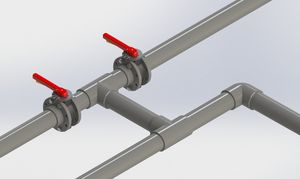

Constanta-2 LLC supplies any elements of plastic piping systems upon the request.

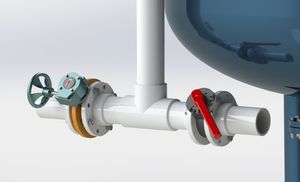

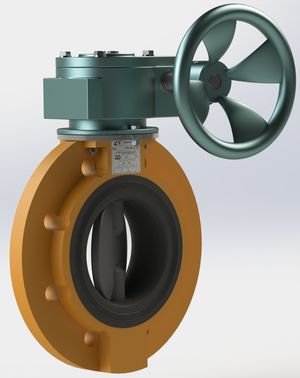

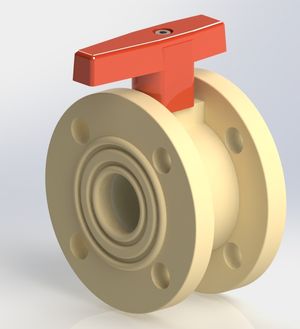

Polymer pipeline fittings developed and manufactured by our company are widely used in all projects performed by the specialists of Constanta-2 LLC.

Назад

Назад