Centres for borehole pumping rods

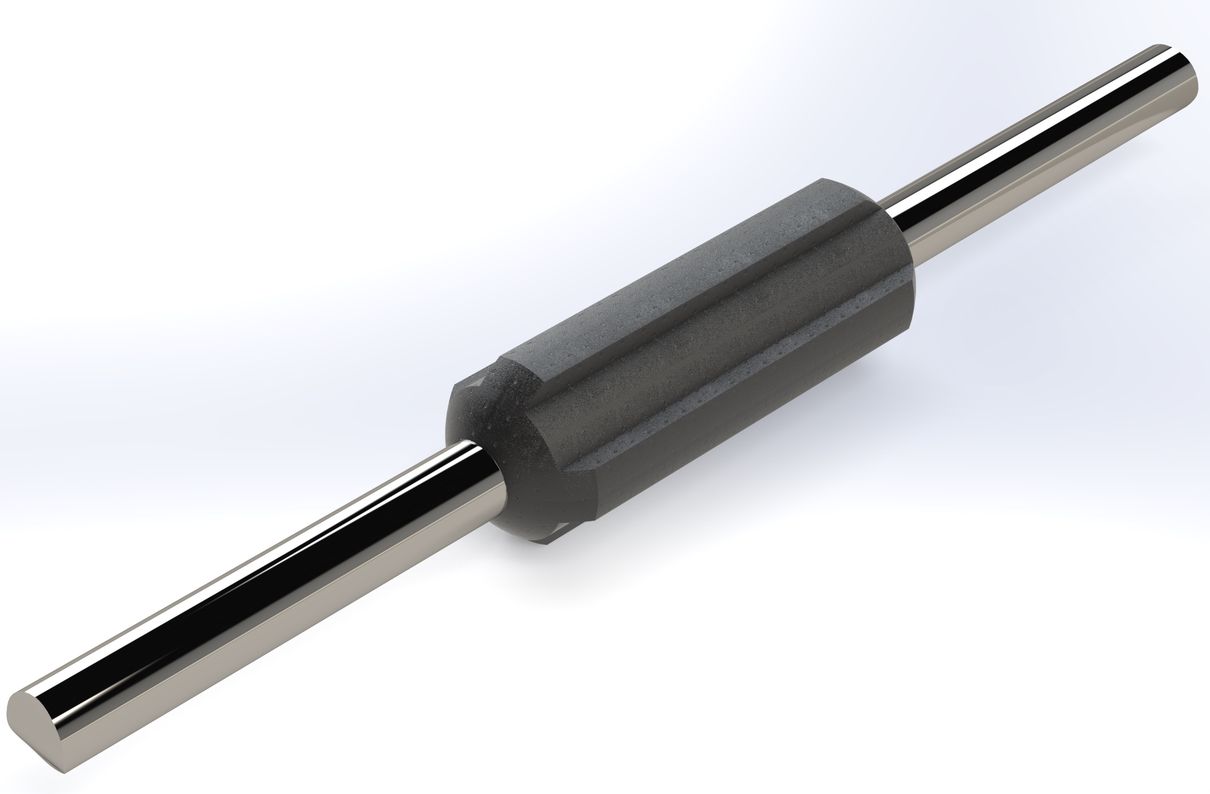

Two thirds (66%) of active wells in the CIS countries (approximately 16.3% of total oil production) are operated by sucker rod pumping units (SRPU). The flow rate of the wells ranges from tens of kilograms per day to several tonnes. The pumps are launched to a depth of several tens of metres to 3000 m, and in some wells to a depth of 3200 ÷ 3400 m. During unit operation the pump rod string performs cyclic reciprocating movements inside the tubing string accompanied by tubing and rod wear. The most intense wear occurs in curved sections of the wellbore.

In addition, the centralisers serve for simultaneous removal of deposits of paraffins, resins, asphaltenes on the tubing surface. The operation of these products is associated with significant abrasive, aggressive and temperature factors.

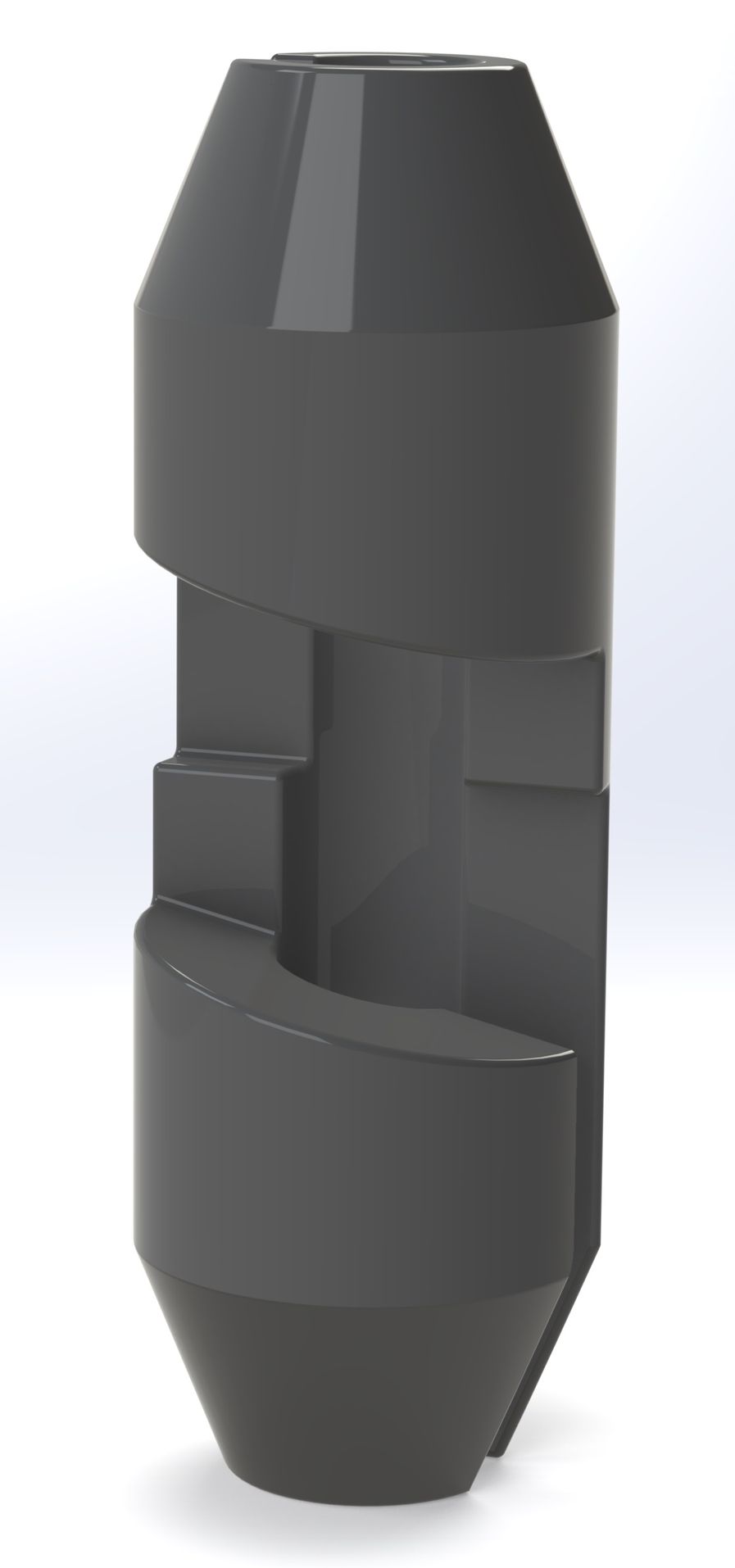

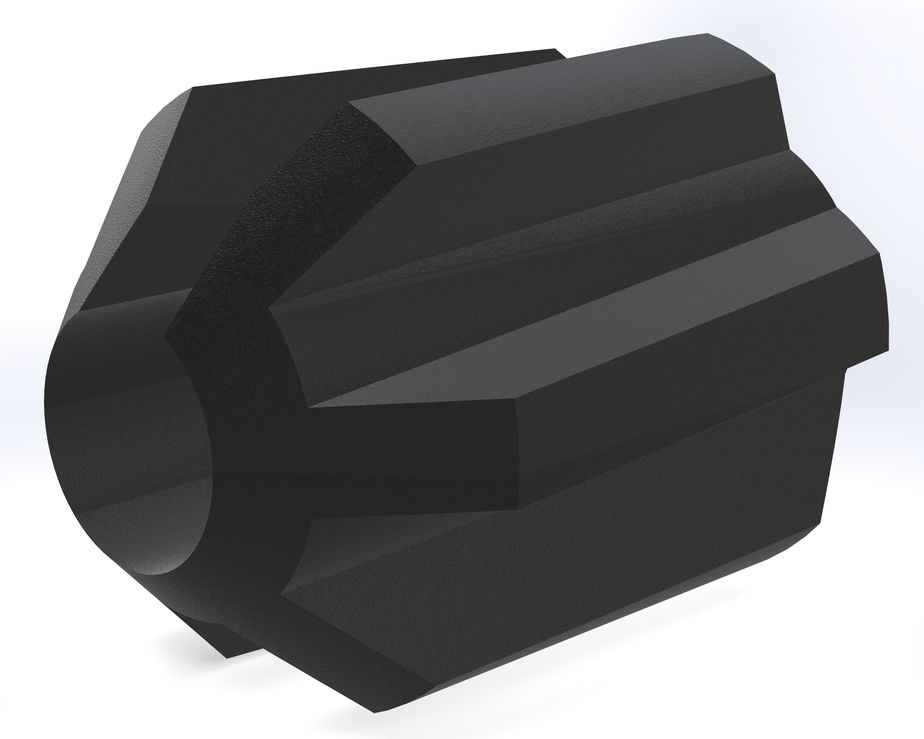

There are many different types of centralisers, divided both by geometry and materials used. The material of the centraliser should have good wear resistance along with a neutral behaviour towards petroleum products.

Nowadays Constanta-2 LLC has an opportunity to manufacture centralizers both in quick-release version and welded as part of the pump rod, and to use wear-resistant rubber and plastic grades as materials.

Branded materials of Constanta-2 LLC used in manufacturing of centralizers are as follows:

| Elastomer based materials | ||

|---|---|---|

| Description | Base | Operative range |

| «К-2-120-12» | Rubber compound based on rolled saturated urethane rubber | -30 ÷ +120°С, up to 1,6 MPa |

| «К-2-160-14» | Rubber compound based on hydrogenated butadiene-nitrile rubber | -60 ÷ +160°С, up to 1,6 MPa |

| «К-2-200-15» | Rubber compound based on fluorinated rubber | -40 ÷ +190°С, up to 80 MPa |

| Polymer based materials | ||

|---|---|---|

| Description | Base | Operative range |

| «Konstaftor-СВМ» | Material based on high-density polyethylene with antifriction and reinforcing fillers | -70 ÷ +100°С, up to 50 MPa |

| «Konstaftor-P36М» | Nylon-based material, with additives improving material characteristics | -100 ÷ +170°С, up to 35 MPa |

| «Konstaftor-1000P» | Polyphenylene sulphide based material | -40 ÷ +190°С, up to 80 MPa |

| «Konstaftor-1000» | Carbon fibre reinforced polyether ether ketone based material | -150 ÷ +300°С, up to 150 MPa |

Назад

Назад