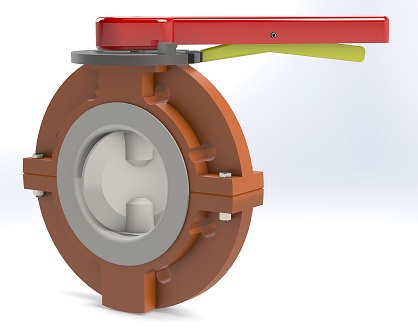

Rotary disc valves in plastic case, disc valve liners (sleeves)

Manufactured according to TS 3760-036-34724672-2019

General parameters of the disc valve:

- DN, mm: 50, 65, 80, 100, 150

- Pressure Pn: up to 1.6 MPa

- Operating temperatures from -70 to +50°C. Operating conditions UHL2; 2.1 according to GOST 15150-69

- Body material: composite based on thermosetting and thermoplastic resins

- Disc material: metal-polymer composite, resistant in corrosive environments

- Operating media temperature from -60 to +150°C

Valve control

- Manual drive (handle)

- Manual drive (gearbox)

- Electric gate actuator

- Electric gate-regulating actuator

Description of the polymer composite disc valve:

- The internal cavity of the disc valve is protected by a corrosion and wear resistant cup of various grades of elastomers, thermoplastics, selected according to the nature of the conducted media.

- Optimal disc configuration ensures high flow capacity. The hydraulic resistance ratio is not more than 1.0 with a fully opened disc.

- Disc valve design ensures tightness in valve according to class A of GOST 9544-2015.

- Design of the liner prevents from the necessity of using additional gaskets when installing the pipeline.

- Disc valve has the minimum construction length and the minimal weight compared to other types of pipeline fittings.

- Disc valve design provides quick replacement of sealing elements and does not require high qualification of workers during repair works.

- Any installation position on the pipeline.

- Plastic cased disc valves are characterised by optimal life cycle cost, absence of expenses for maintenance of appearance preserved during the whole service life.

- Interflange connection to the pipeline. In case of installation on pipelines with large flange distances, the valves can be supplied with adapter inserts to compensate for the difference in length.

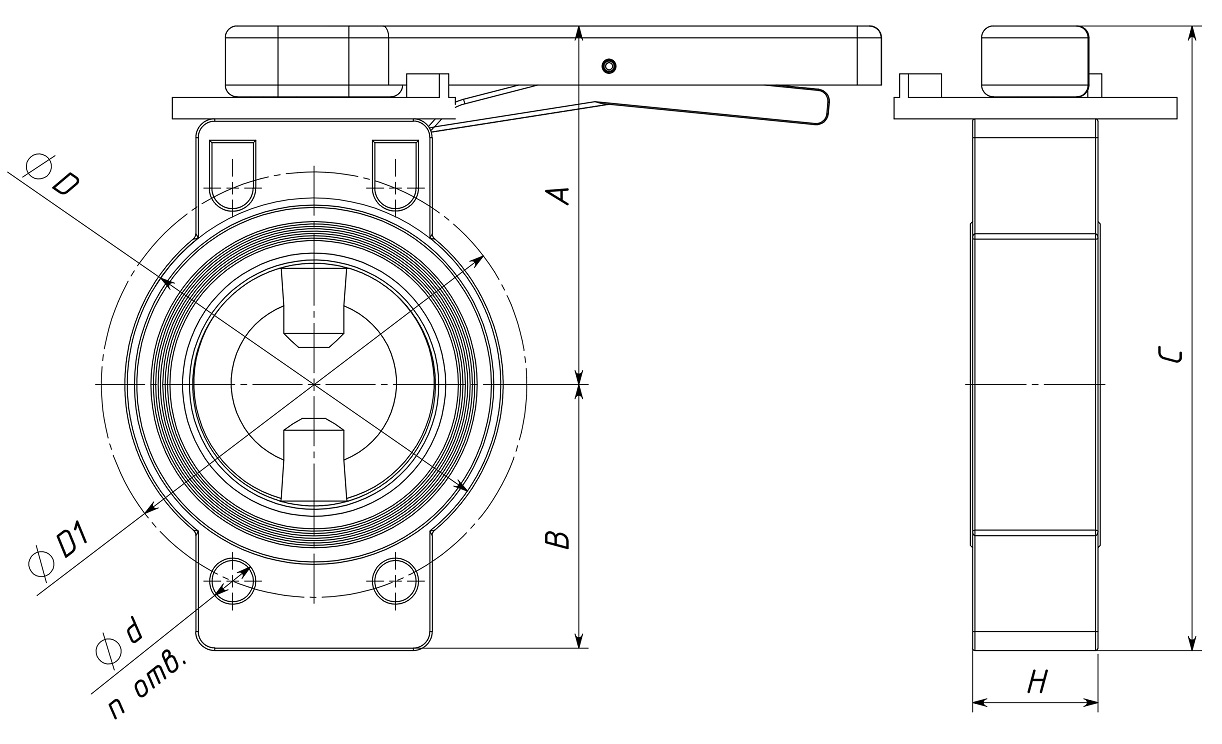

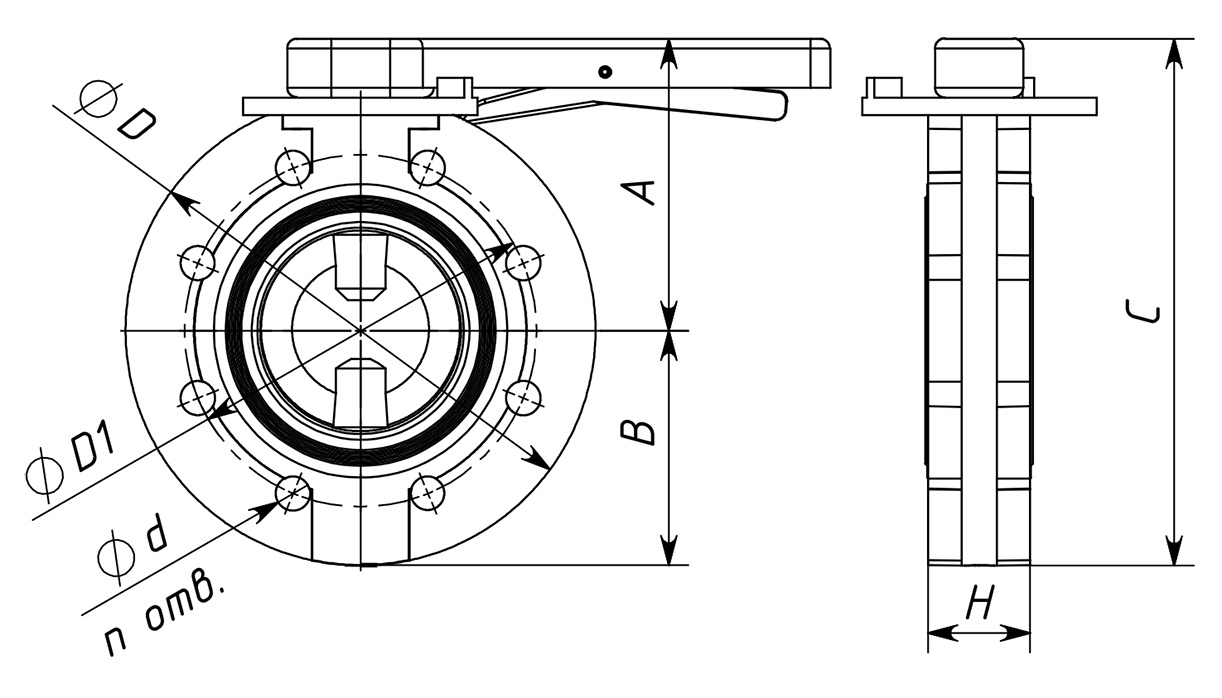

Disk valve drawing Np 1.0 ; 1.6 MPa

| DN, mm | Overall and connection dimensions, mm | Weight, kg max* | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | D1 | H | d/n | ||

| 50 | 115 | 90 | 215 | 106 | 125 | 41 | 18/2 | 1,23 |

| 65 | 123 | 100 | 215 | 125 | 145 | 46 | 18/4 | 1,72 |

| 80 | 132 | 110 | 215 | 140 | 160 | 43 | 18/4 | 1,89 |

| 100 | 153 | 120 | 215 | 160 | 180 | 51 | 18/4 | 2,6 |

| 150 | 195 | 165 | 300 | 216 | 240 | 70 | 22/4 | 5,67 |

Disk valve drawing Np 0.6 MPa

| DN, mm | Overall and connection dimensions, mm | Weight, kg max* | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | D1 | H | d/n | ||

| 50 | 115 | 90 | 215 | 180 | 110 | 41 | 14/4 | 1,6 |

| 65 | 123 | 100 | 215 | 185 | 130 | 46 | 14/4 | 2,1 |

| 80 | 132 | 110 | 215 | 202 | 150 | 43 | 18/4 | 2,4 |

| 100 | 153 | 120 | 215 | 225 | 170 | 51 | 18/4 | 2,7 |

| 150 | 195 | 165 | 300 | 300 | 225 | 56 | 18/8 | 5,67 |

Disc valves application areas and recommended design of sealing elements:

Electric disc valve

Gearbox disc valve

Handle disc valve

| No. | Operating media | Temperature, °C | Sleeve material |

|---|---|---|---|

| 1 | Food and biological | from -40 to +150 | NBR, EPDM, SI rubbers |

| 2 | Chemically active (acidic and alkaline) with a medium aggressive level (concentrations up to 20%) | from -30 to +150 | SBF, FPM, IR rubbers |

| 3 | Petroleum products | from -40 to +150 | EPDM, FPM rubbers |

| 4 | Domestic, industrial, sea water | from 0 to +150 | SBR, EPDM, IR rubbers |

| 5 | Gaseous media | from -40 to +150 | NBR, IR, SI rubbers |

| 6 | Abrasive media | from -30 to +120 | PUR, IR, IIR rubbers |

Reliability parameters for disc valves:

- Service life of disc gate not less than 10 years.

- Service life not less than 6000 cycles.

- Warranty period of operation is 12 months.

Fluoroplastic disc valve with PTFE disc and PTFE rubber collar. This solution is extremely resistant to all media pumped through pipeline systems.

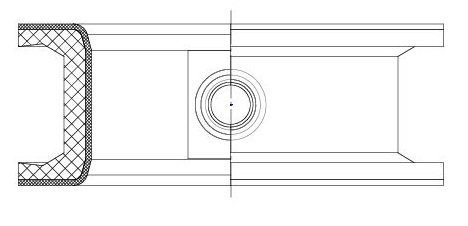

Inserts (sleeves) of disc valves

Disc valve insert drawing

Disc valve insert

Diameter Nominal: DN 20 - DN 250

Material: Elastomers, fluoroplastics, thermoplastic elastomers

The company performs warranty and post-warranty service of disc valves as well as supplies spare parts.

Назад

Назад