Impellers and submersible pump casings from polymer materials, friction couples for mechanical seals

1. PCM impellers and submersible pump casings

The disadvantages of rod pumps are limited depth of its suspension and low oil delivery from the wells. Large amount of formation water comes from the wells together with oil at the final stage of operation, and the use of rod pumps becomes inefficient.

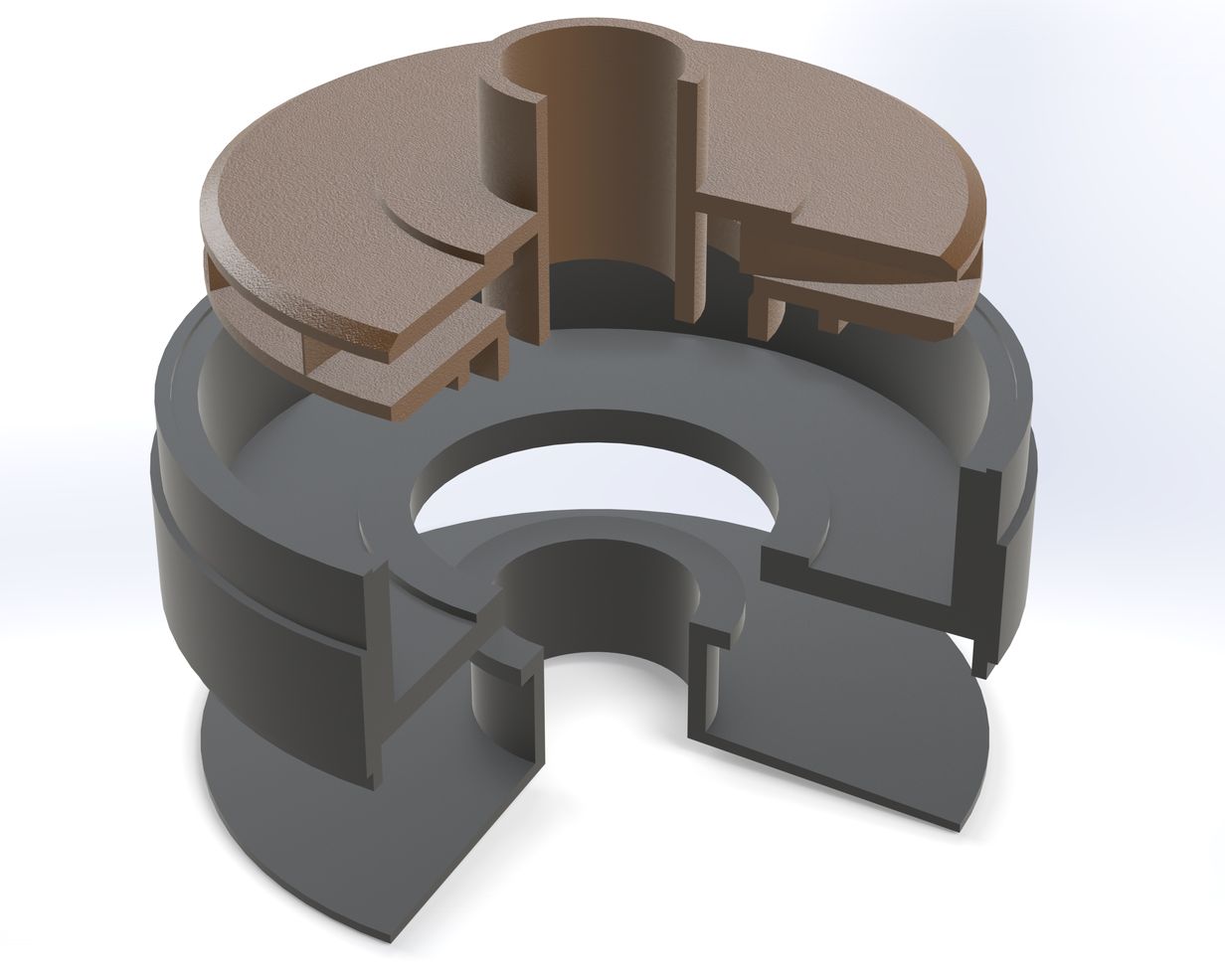

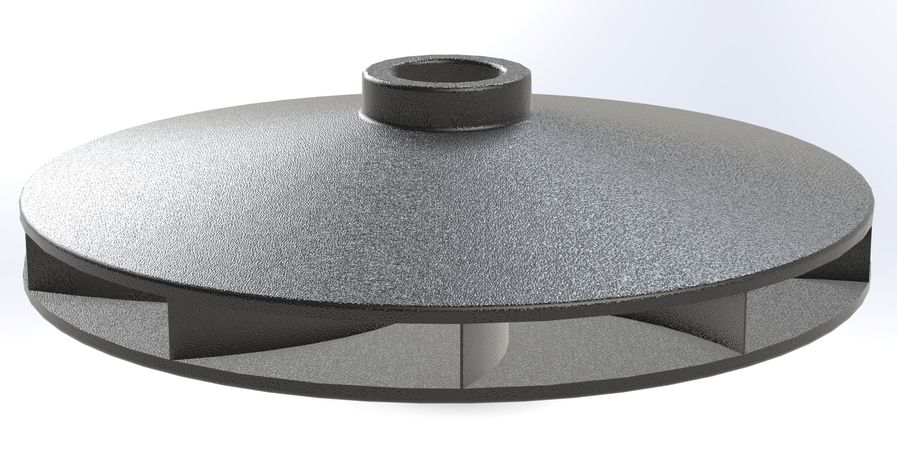

These disadvantages are eliminated by electric submersible pumps. Submersible pumps are small-sized (in diameter) centrifugal, sectional, multistage pumps with electric motor drive. The number of stages in a pump unit can range from 220 to 400. Each stage develops a head from 3 to 7 metres of water column. The pump stage consists of a casing, cover and impeller (main working parts).

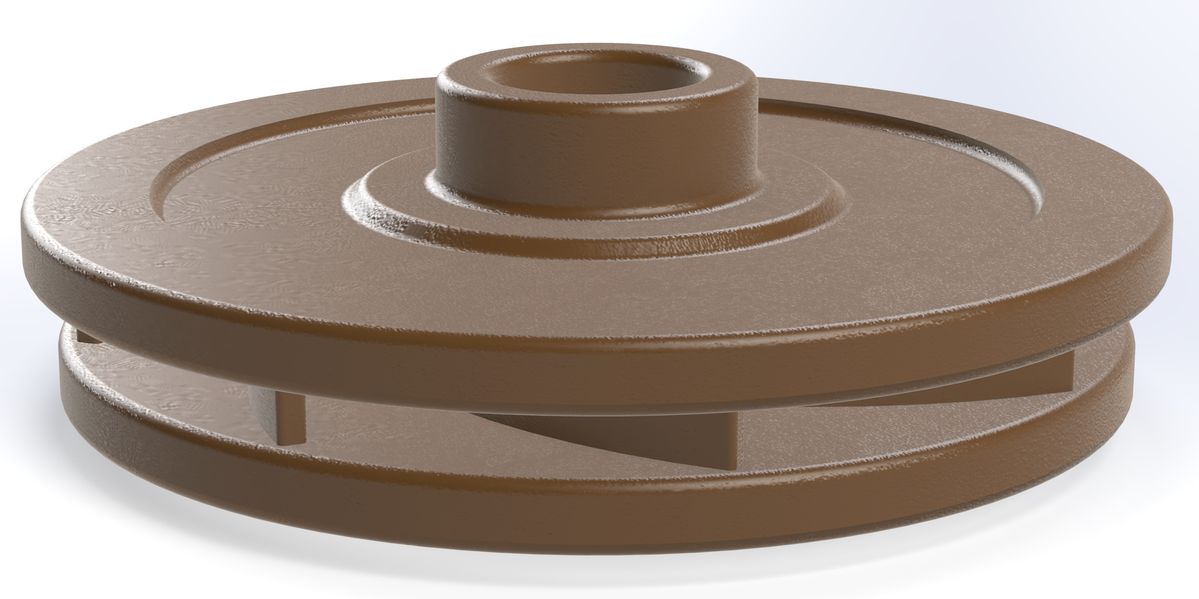

The use of modern polymer materials in the production of ESP impellers allows Konstanta-2 LLC to create pump units that are free from corrosion and have a reduced rate of salt deposition on them.

The low-adhesion ESP, compared to the traditional ESP, reduces operating costs, the number of repairs, and increases the equipment's operating time per failure.

Benefits of polymer applications.

- High corrosion resistance and purity of polymer flow channels, low adhesion and non-magnetic properties of the material, as well as absence of the possibility of galvanic pairs formation provide a reduction in the rate of salt and other deposits by at least 3 times compared to metal impellers, as well as reduce the probability of clogging by non-abrasive mechanical impurities.

- High manufacturing accuracy and low weight of polymer impellers (4-5 times less than metal impellers) in combination with intermediate bearings provide high balance of shaft rotation in the entire range of adjustable motor frequencies, reducing wear of radial friction couples.

- Low rotor weight, which is 2.5 times less than for ESP with metal impellers, ensures reduced starting currents and smooth motor start-up.

- High purity of flow channels, low adhesion and high corrosion resistance of the impeller material ensure reduction of heating temperature of formation fluid, which helps to reduce the probability of salt precipitation.

| Polymer based materials | ||

|---|---|---|

| Name | Base | Operating range |

| Konstaftor-СВМ | Material based on high-density polyethylene with antifriction and reinforcing fillers | -70 ÷ +100°С, up to 50 MPa |

| Konstaftor -P36М | Nylon-based material, with additives to improve material characteristics | -100 ÷ +170°С, up to 35 MPa |

| Konstaftor -1000P | Polyphenylene sulphide based material | -40 ÷ +190°С, up to 80 MPa |

| Konstaftor -1000 | Carbon fibre reinforced polyether ether ketone based material | -150 ÷ +300°С, up to 150 MPa |

2. Friction couples for mechanical seals.

Mechanical seals were invented in 1895-1900, which started to be used in refrigeration compressors, centrifugal pumps and other machines only in the 20s.

| Operating properties | Sliding velocities, m/s | Temperature, °C | Pressure, MPa | |||

|---|---|---|---|---|---|---|

| up to 10 | up to 300 | up to 75 | ||||

| Composite materials | ||||||

| Performance | Konstaftor 300 | Konstaftor 1000 | AFGM, 7В2С | FKN-7, FKN-14 | F4UB20 (flubon) | F4BR20 |

Назад

Назад