Diaphragms, PTFE bellows and its composites

Diaphragm separating seals represent a dense partition between the sealed media, have a strongly developed surface and shape, providing a large deformation under the action of differential pressure of media. Characteristic operating properties of diaphragm seals: the lowest (compared to other types of seals) leakages, determined only by diffusion of media; low permissible pressure drops between media; limited permissible displacements. The properties of diaphragm seals are strongly dependent on the properties of the materials from which they are produced. Thus, metal diaphragms are recognised for their high stiffness and low deformability. Rubber and rubber-fibre diaphragms - diaphragms can provide large deformations, but have a limited operating temperature range and have higher diffusion permeability than bellows. Plastic diaphragms and bellows (e.g. fluoroplastic) are used for aggressive media. Polymer and metal-polymer diaphragms are the most suitable for difficult operating conditions.

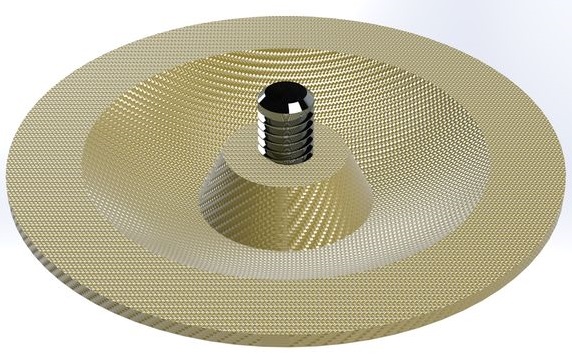

1. PTFE reinforced diaphragms

Glass fibre-reinforced fluoroplastic diaphragms are produced according to a patented technology based on the know-how of Constanta-2 LLC.

Fiberglass reinforcement allows to increase the strength sharply without losing the basic properties inherent to fluoroplastic. Thus, a combination of unique corrosion resistance and antidiffusion properties with the possibility of operation at high pressures up to 2.5 MPa and medium temperatures up to 250 °C can be achieved.

Higher strength is achieved by reinforcing fluoroplastic with metal mesh or foil.

Dimensions of supplied diaphragms: up to 800 mm.

Material: foiled fluoroplastic, glass fibre and metal mesh reinforced polymers.

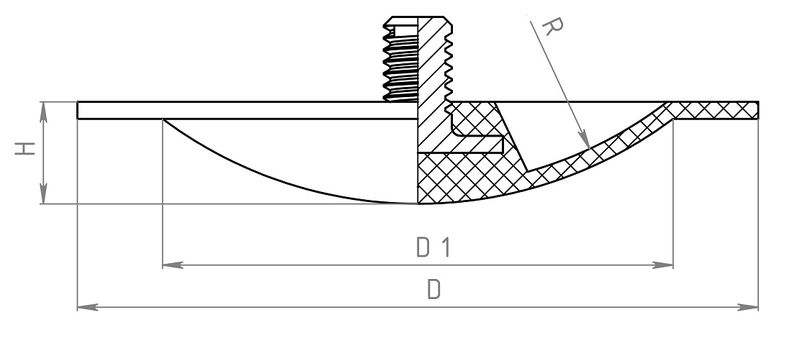

Reinforced PTFE diaphragms for valve 15ch75p.

Constanta-2 LLC produces standard diaphragms for valves type 15ch75p of the following standard dimensions:

| DN, mm | D, mm | D1, mm | H, mm | R, mm |

| 15 | 55 | 43 | 6 | 53 |

| 20 | 66 | 50 | 10 | 70 |

| 25 | 85 | 62 | 17 | 63 |

| 32 | 98 | 72 | 7,5 | 95 |

| 40 | 115 | 90 | 10 | 125 |

| 50 | 130 | 110 | 13 | 118 |

| 80 | 160 | 140 | 22,6 | 120 |

| 100 | 222 | 178 | 27,6 | 160 |

The fastening screw can be supplied in black or stainless steel versions upon the customer's agreement.

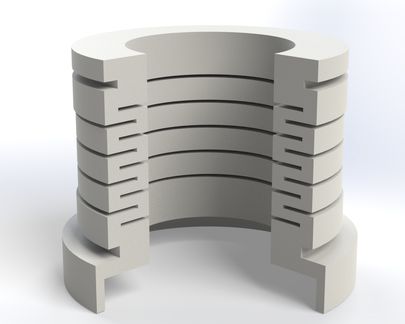

2. PTFE bellows for aggressive media at high temperatures and pressures

Corrugated diaphragms and bellows have a greater capacity for deformation.

Bellows is an elastic single-layer or multi-layer corrugated shell from metal, non-metallic and composite materials that retains strength and density under multi-cycle deformations of compression, bending and their combinations under the influence of internal or external pressure, temperature and mechanical loads. Bellows are widely used in pipeline valves as a sealing, sensing and force element. Bellows are used to compensate vibrations, thermal expansion, axial and angular displacement of equipment elements and pipelines. Bellows compensators are used for compensation of thermal expansion, compensation of misalignment, isolation of vibration loads and flow of transported medium in pipeline systems.

Bellows produced from PTFE-4, its compositions and other polymers and composites are suitable for use in pumps, piping systems and apparatuses as compensating elements. PTFE bellows can work in contact with highly aggressive media. Fluoroplastic bellows are manufactured according to a patented waste-free technology that eliminates machining, providing high tightness and serviceability at elevated temperatures.

Назад

Назад