Shut-off valves and seals from polymer composite materials for intermodal tank containers

Shut-off valves and seals from polymer composite materials for intermodal tank containers. Shut-off valves in tank-containers and tanks for liquid agents transportation are operated under extremely harsh conditions: there are various corrosive-active media with variable pH, temperature up to 60 °C and pressure up to 4 atm, dynamic effects on the valves during transportation and loading-unloading, low ambient temperature up to -40 °C.

Currently installed imported valves from stainless steel or lined with fluoroplastic are characterised by low corrosion resistance in highly corrosive environments, high cost, low vandal resistance.

Shut-off valves from polymer composite materials fulfil these requirements most effectively, as they have a number of advantages:

- combination in polymer composites of high specific strength, high corrosion resistance and low cost;

- absence of emissions through seals and impact on the external environment;

- has high reliability and durability;

- the most technologically advanced in manufacturing, providing low cost;

- resistance to unauthorised external anthropogenic impact;

- fire resistance;

- maintainability;

- simplicity of installation and operation, particularly important as the operating personnel has the average qualification in most cases;

- easy to clean from aggressive and adhesion-active media.

The importance of having national analogues in conditions of influence of difficultly predictable external factors stimulated the development of shut-off valves for tanks of aggressive media transportation made of composite materials. Constanta-2 LLC is the only manufacturer of such equipment in Russia.

The choice of materials for the above mentioned products was based on the following postulates. High-strength material with maximum value of specific strength, inexpensive and aggressive resistant is necessary. Composite materials based on reactoplastics or thermoplastics dispersely-reinforced and reinforced with long fibres (according to foreign terminology - LFT composites) best correspond to these criteria, which is confirmed by the data of the table.

Comparative characteristics of composites and stainless steel

| Konstaftor-G | Konstaftor-1000P | Konstaftor-DSV PP | 12Х18Н10Т | |

| Specific strength, kg f•cm/g | 450 | 620 | 250 | 250 |

| Corrosion resistance | ++ | +++ | ++ | + |

| Relative cost, roub./kg | 1 | 1,5 | 0,7 | 10 |

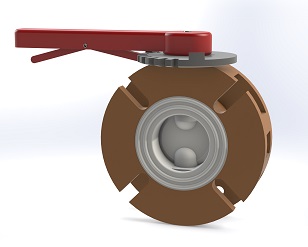

1. Disc valve

The disc shutter (DS) is a product consisting of a rotary disc sealed by an elastomeric collar installed in the body. The metal-plastic rotary disc being manufactured from glass fibre reinforced ultra-high molecular weight polyethylene or fluoroplastic allows pumping media of any aggressiveness. The single-section body manufactured from reinforced thermosetting plastic has high chemical resistance, strength and rigidity. The cup is manufactured from material with high aggressive and heat resistance, the design of the cup eliminates the need for additional gaskets during installation.

Distinctive properties of the DS are as follows:

- patented design of the spindle-disc interface, resulting in high rigidity against bending loads from external pressure;

- double stem seal and a spring-loaded cup seal.

2. Ball cock

The ball cock (BC) consists of a two-section body, ball, spindle and seals. Distinctive features of ball cocks from composite material are as follows:

- simplicity of construction, operation and maintainability;

- highly efficient patented ball sealing system, eliminating the need for compression during operation;

- low operating torque;

- double stem seal, preventing leakage;

- small dimensions and weight.

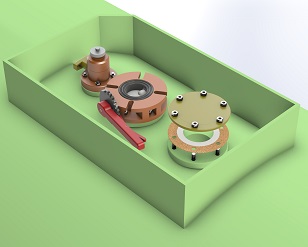

Description of pipeline valves from composite materials

| Disc shutter | Ball cock | |

| Nominal diameter | 50, 80 | 25, 32, 80 |

| Operating temperature, °C | -60 ÷ +150 | -60 ÷ +150 |

| Maximum pressure, MPa | 1,0 | 2,5 |

| Connection | Flange | Flange, coupling |

| Leak resistance, GOST 54808-2011 | Class А | Class А |

| Resource, cycles/years | 6000/10 | 6000/10 |

| Media direction | any direction | any direction |

| Installing position | any position | any position |

| Hydraulic resistance | not more than 1 | not more than 0.5 |

| Spindle torque | 10 - 30 | 5 - 20 |

3. Relief valve

The relief valve (RV) consists of a body, a cover and the spring loaded valve. It is structurally the same as a steel valve except for the spring design. The springs are made of conventional spring steel and encapsulated in a sealed PTFE shell to protect against corrosion. RV are manufactured with nominal bore 80 and designed for operation at temperatures from -60 to +150 °C at pressure up to 1 MPa. RV are available with both flange and coupling connection, however, we advise flange connection for composite materials as well as for other types of fittings, as threaded connection is not very reliable.

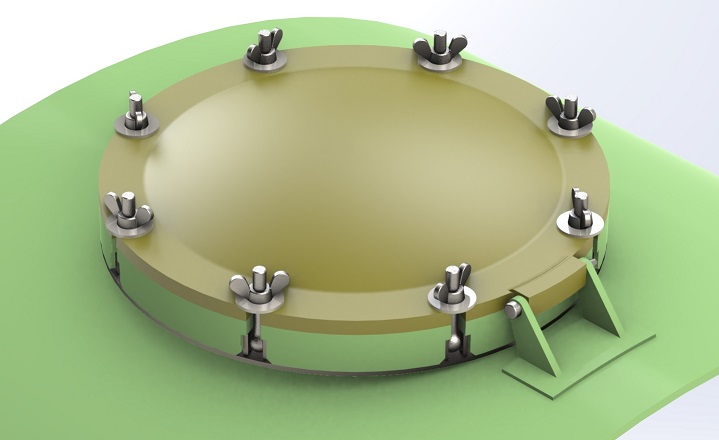

4. Access hatch

The access hatch is a similar steel device with a nominal bore 500, designed for pressure up to 0.6 MPa at temperatures from -60 to +150 °С. Its main distinguishing features are several times less weight and technological solution, resulting in low cost. The table shows comparative weight properties of steel and composite reinforcement.

Comparison of composite and corrosion-resistant steel equipment weights.

| Equipment | Access hatch DN500 | Hatch cover DN500 | Relief valve DN80 | Drain line disc shutter DN80 | Airline ball cock DN32 |

| Composite equipment weight, kg | 33 | 6 | 3,6 | 3 | 1,4 |

| Steel equipment weight, kg | 116 | 17 | 7,1 | 6 | 2,9 |

The offered solutions are protected by patents of the Russian Federation and have no analogues.

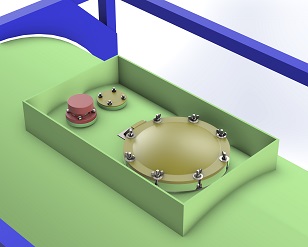

Example of the equipment installation on tank container.

Interchangeability and similar connection dimensions allow using PCM valves on steel tank-containers as well. Obviously, the design and technological solutions demonstrated here are also relevant for ship pipeline fittings and for completion of other vessel equipment and on steel tank containers, since this equipment can be easily adapted.

Seals.

All valves are fitted with native seals:

Access hatch seal produced according to the technology of encapsulating rubber on the outside with a continuous fluoroplastic shell for manholes DN3OO and DN500

Combined rubber and fluoroplastic seals with diameters from 10 to 500 mm and cross-sectional diameters from 1.4 to 15 mm

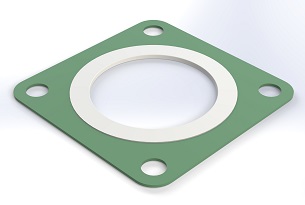

Fluoroplastic-propane flange gaskets DN15-DN250 (type 1)

Fluoroplastic-propane flange gaskets DN15-DN250 (type 2)

Назад

Назад