Fluoroplastic encapsulated rubber rings (RFR) for harsh environments

We kindly ask you to fill in our Questionnaire if you are interested in our products and would like to place an order for production. This will help to provide all the necessary information and save the time.

Fluoroplastic encapsulated rubber rings (RFR) are used for sealing in movable and fixed joints operating in conditions of simultaneous exposure to high temperatures, pressures, aggressive media. Constanta-2 LLC is the only Russian manufacturer of O-rings in fluoroplastic encapsulated with diameter from 10 to 2000 mm, the dimensions of which correspond to GOST 9833-73 as well as non-standard sizes. Elastically deformable RFR rings are produced according to TS 22.19.73-006-34724672-2016 using the technology developed by the employees of Konstanta-2 LLC and protected by a patent of the Russian Federation. The design of the rings allows combining high elastic properties inherent to elastomers with heat resistance, aggression resistance, antifriction properties typical for fluoroplastic. Encapsulated rings are manufactured using a patented technology by welding the shell around a rubber core, which allows to produce rings with a shell of almost any thickness - from 0.2 to 3 mm. The shells are subjected to 100% tightness control using ‘Penetrant’ penetrating compounds.

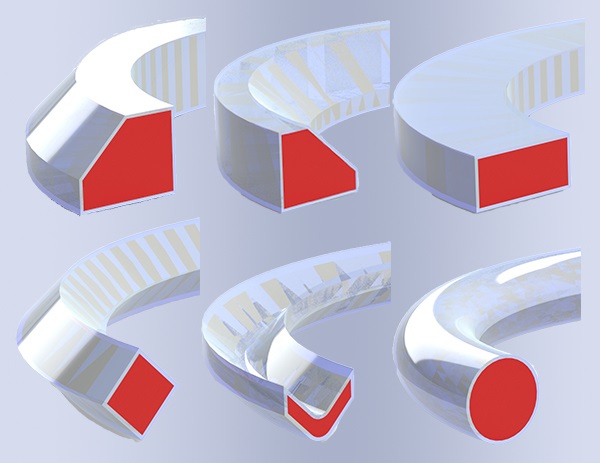

Thus, a group of PTFE-rubber seals has emerged in the class of composite seals, the simplest of which are PTFE-rubber rings (RFR). In addition to encapsulated O-rings, we also offer our customers profiled versions of combined rubber PTFE seals. The main thing that unites them is that the rubber core from silicone or fluoroelastomer provides elastic properties of the seal and, accordingly, the proper level of contact pressure on the mating surfaces in the whole temperature range from -60°C to +220°C, and the shell from fluoroplastic copolymers F4MB or F-50 provides chemical stability in all industrially used media, increased strength and heat resistance determine high parameters of operation at temperatures (up to 250°C) and pressures (up to 100 MPa). Elasticity of rubber core and absence of cold-fluidity in used fluoroplastic grades eliminate flow under load up to maximum pressures of 100 MPa and elastic recovery after loading.

The possibility of changing the hardness of the rubber core (from 40 to 85 according to Shore A) and wall thickness of the shell (from 0.2 to 3 mm) within a wide range, these characteristics determine the sealing ability, the shape of the cross-section and dimensions of the combined seal, the use of different shell materials allow to adjust the properties of the sealing unit. In this way the use of rubber cores based on siloxane rubbers and 3 fluoroplastic shells allows to achieve elasticity of seals at low temperatures and reduces the temperature threshold of applicability down to -60°C. The appliance of radiation-resistant F-50, F-40 fluoroplastic grades in the shell material instead of PTFE, which have two orders of magnitude higher radiation resistance, allows to use this solution in the nuclear industry.

Our specialists can perform engineering design of the sealing unit according to the Customer's technical specification.

Manufactured in accordance with TS 22.19.73-006-34724672-2016.

The composite seal is a rubber ring encapsulated in a seamless fluoroplastic F-4MB (FEP) or F-50 (PFA) shell. The shell thickness varies from 0.2 to 3.0 mm, depending on the ring size and operating conditions.

| Basic parameters: | combination of elastic properties of rubber core with high chemical resistance and heat resistance of fluoroplastic shell, low coefficient of friction. | |

| Operating temperature: | from -60 to +250°С | |

| Metal friction coefficient: | 0.1 – 0.2 | |

| Operating media: | concentrated solutions of acids and alkalis, hydrocarbons, solvents, aggressive gases, mixtures of various aggressive substances. | |

| Ring dimensions | Core diameter D, mm | 10 - 2000 |

| Section d, mm | 1,9; 2,5; 3,6; 4,0; 5,0; 5,8; 7; 8,5; 12,8 | |

| Fluoroplastic shell thickness, mm | 0,2 - 3,0 | |

| Core material: | fluoroelastomer (viton), silicone elastomer. | |

| Maximum relative travel speed, m/sec | Up to 5 | |

| Maximum design operating pressure, MPa | 100 | |

| Elastic recovery after deformation, % | Not less than 90 | |

| Gas permeability, decompression | None | |

Ring designation for placing an order according to TS 22.19.73-006-34724672-2016:

RFR 66,0-73,2-3,6-S50-F4MB RFR – fluoroplastic rubber ring; 66.0 – core diameter 66 mm; 73.2 – outside diameter 73.2 mm; 3.6 – section diameter 3.6 mm; С50 – rubber core grade and hardness: S-silicone, F- fluorocarbon; 50- Shore A hardness; F4MB – shell grade: F4MB — F4MB fluoroplastic, F50 —F50 fluoroplastic; Fluoroplastic shell thickness 0.25 - 0.3 mm.Application

Fluoroplastic encapsulated rubber rings (hereinafter: RFR or encapsulated rings) are designed to seal different types of fixed and movable joints in hydraulic and pneumatic devices, stop valves.

The presence of fluoroplastic sheath allows RFR to be applied in equipment where a contact with food products is possible and appropriate certificates are required.

The unique in its universal chemical resistance fluoroplastic sheath allows to use RFR as a part of equipment assemblies in contact with aggressive media of variable nature or unpredictable composition. So application of RFR in mechanical seals and pump units allows to solve sometimes insoluble problems of joint influence of environmental factors. It is possible to produce seals not only in round, but also rectangular, trapezoidal and other cross-sections, which significantly expands the application areas.

It is necessary to note that rubber-fluoroplastic rings produced by our company are an example of advanced import substitution as the exclusive technology of its production, developed at our enterprise in the late 90's and protected by a patent of the Russian Federation, was the result of the desire to produce products similar to the encapsulated rings already available on the foreign market of mechanical engineering - universal seals, which are the solution to the problem of providing resistance to variable media. Nowadays LLC "Konstanta-2", being the only Russian manufacturer of rubber-fluoroelast rings, supplies its consumers with products not only comparable to imported products, but also offers a more diverse range of performance of these unique seals.

The range of RFR is varied, including the use of shells of different thicknesses and cores from minimum to increased hardness, which allows these seals to be used even in highly stressed assemblies with rotary and reciprocating motion.

The latest development is the use of combined rubber-fluoroplastic seals for sealing the plug-ball in ball valves. The proposed technical solution consists in replacing the seal made of polytetrafluoroethylene with a combined rubber-fluoroplastic seal of similar or circular cross-section and dimensions.

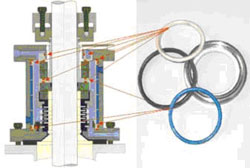

Example of encapsulated rings used in the mechanical seal 130 UTDS (NPK ANOD).

Назад

Назад