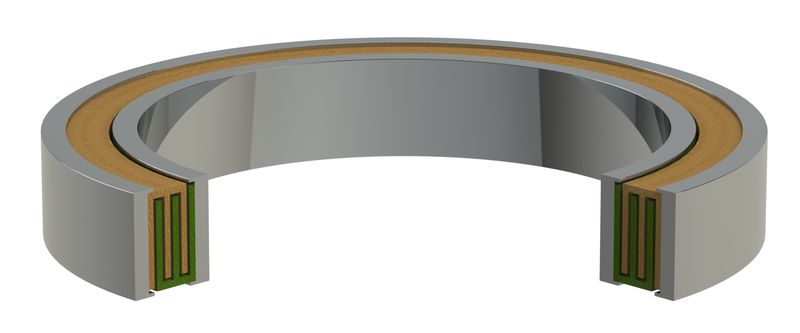

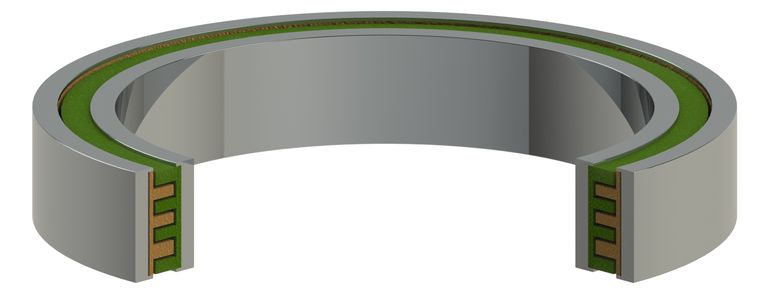

Labyrinth seals

Labyrinth seal is a set of two polymer rings, one of which is fixed on the shaft and the other in the cylinder housing, forming a non-contact sinuous gap filled with grease to seal and protect the bearing from aggressive environmental conditions and increase the service life. The most popular labyrinth bearing seals are used in the manufacture and operation of conveyor rollers as well as for bearing protection in the operation of various equipment in agriculture.

-

Labyrinth seals benefits:

- low internal lubrication friction,

- wear resistance,

- ease of operation,

- high peripheral shaft speeds

Labyrinth seals are used to protect against lubricant leakage and ingress of moisture and dirt from the outside environment, more often in combination with other seal types. More than two grooves are necessary for particularly high protection requirements and difficult operating conditions.

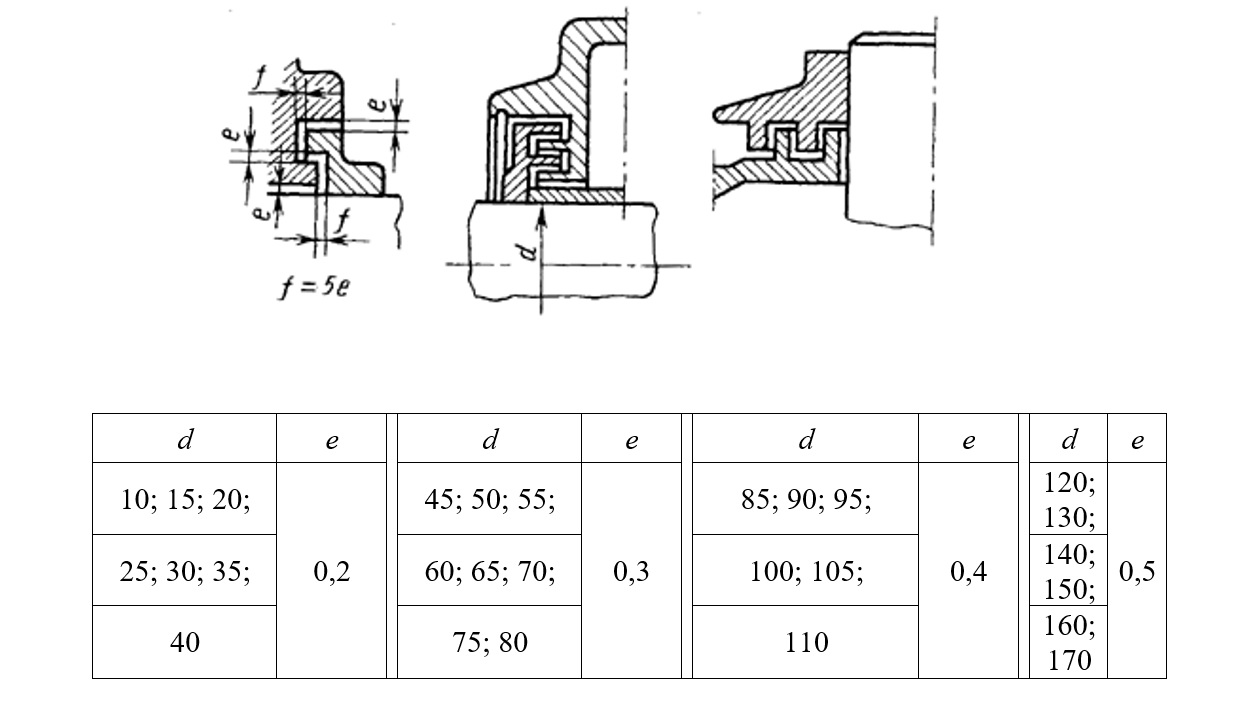

Basic dimensions for labyrinth seals, mm

Labyrinth seals are used at high circumferential speeds and temperatures where there is no possibility of fitting contact seals. Labyrinth seals can operate at almost all speeds and high temperatures.

The ultimate advantage is the extremely low friction, which results in higher rotational speeds.

There are stepped and straight-through labyrinth seals. The sealing action is based on creating the smallest possible gap of complex configuration between fixed and rotating parts. Benefits of labyrinth seals over other types of seals are:

- wear resistance;

- low internal lubrication friction;

- no limit for peripheral shaft speeds;

- ease of operation.

The material for seals is selected depending on the purpose of the machines and apparatus and its operating conditions, the principal of which are as follows:

- application severity;

- temperature;

- pressure;

- viscous-fluid characteristics of the operating media;

- design features of the device itself.

Some types oflabyrinth seals are produced from high quality and high strength plastics. These devices are characterised by high chemical resistance to a variety of substances, bacteria and fungi. This quality is of particular value in the food and consumer goods industries. They are also characterised by high corrosion resistance to water.

Назад

Назад